Alkyd Resin & Styrene Emulsion Manufacturing Plant

Advanced manufacturing technology for alkyd resins and water-based emulsions for paints, coatings, and industrial applications

Alkyd Resin & Styrene Emulsion Manufacturing Plant

Alkyd Resins:

- •Long, Medium, Short

- •Oil and Styrenated Alkyds

- •Acrylic and Phenolic Resins

- •Resins for Paints & Coatings

- •Polyamides & CNSL Resins

- •Epoxy and PU Resins

Water Based Emulsions:

- •Styrene and Pure Acrylics for Paints & Coatings

- •Textile and Paper Emulsions

- •Emulsions and Binders for Adhesives and Packaging

- •Cement and Waterproofing Aids

Alkyd Resin Manufacturing Overview

Watch our comprehensive alkyd resin and styrene emulsion manufacturing process in action, showcasing the complete production process from raw materials to finished product.

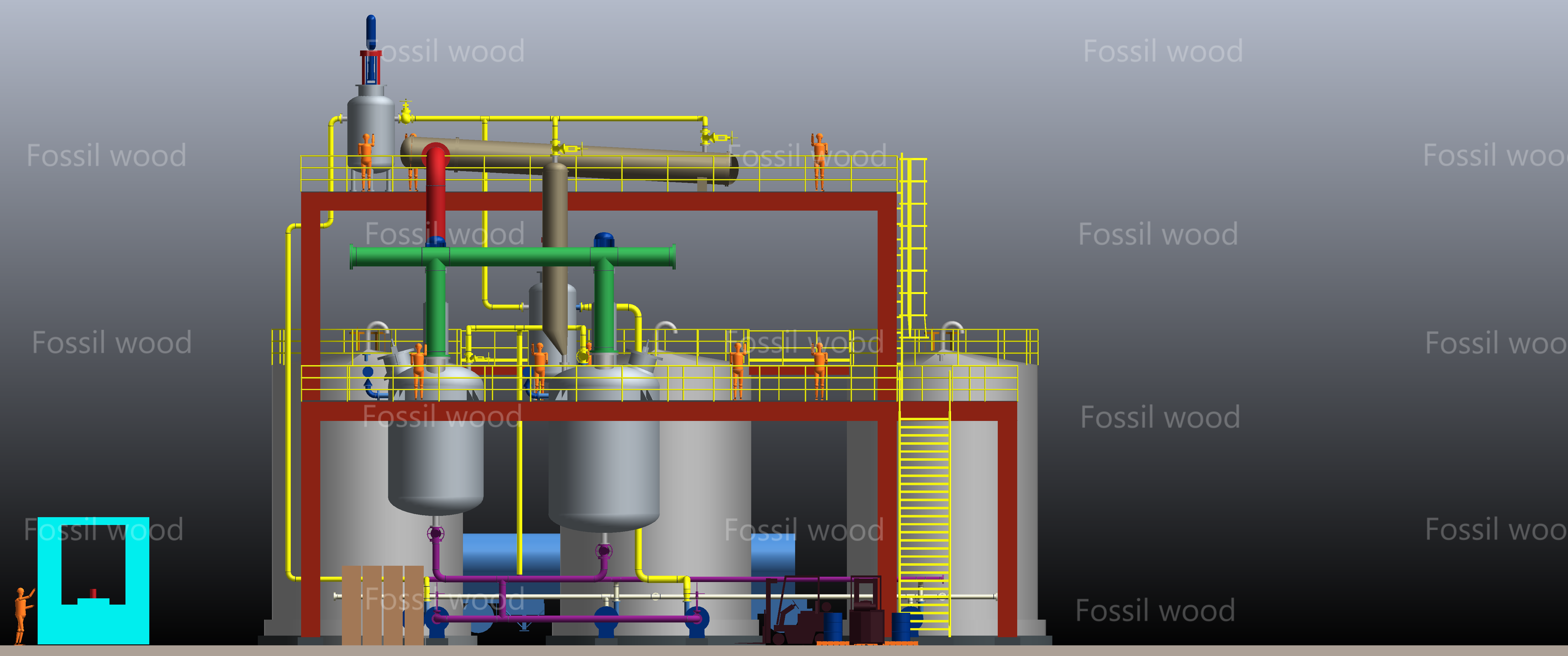

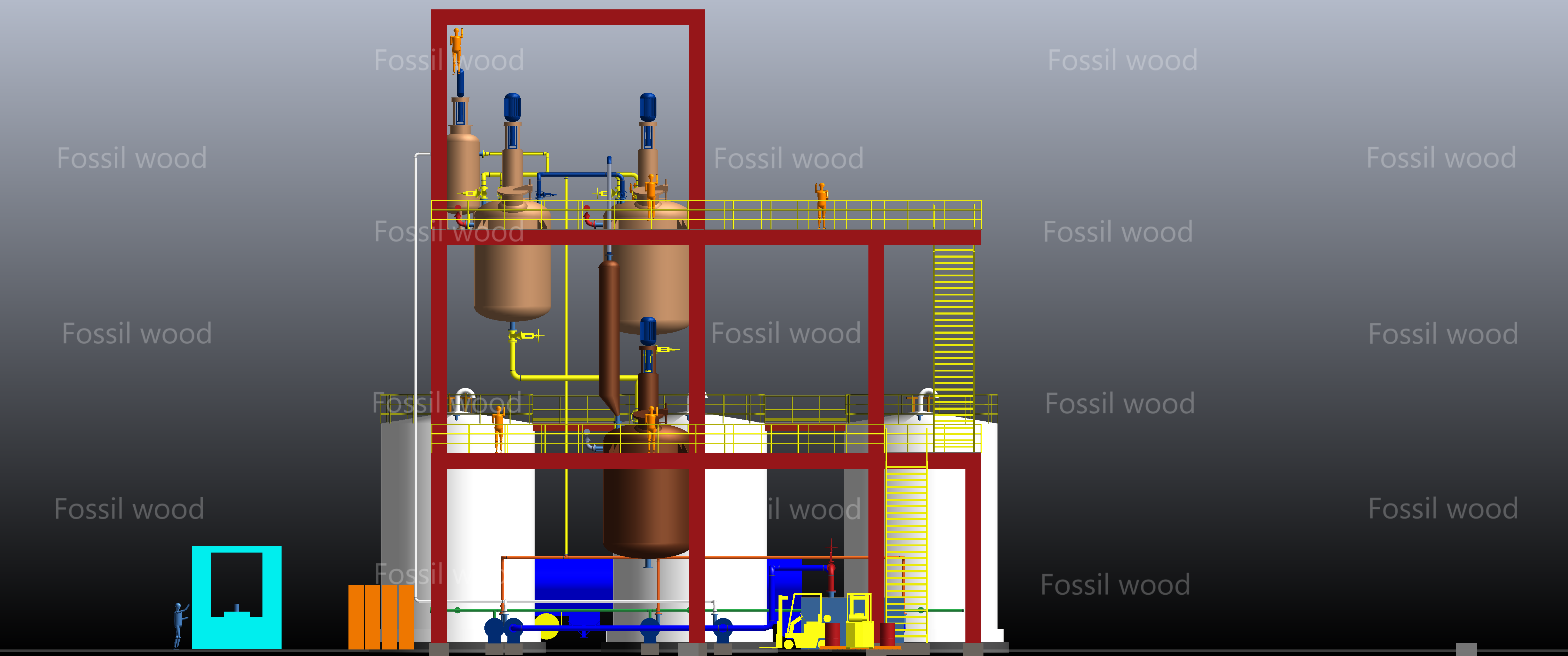

Alkyd Resin Plants

Brief Process

Raw materials are pumped from storage tanks into a reactor, heated to 240-250°C, followed by catalyst addition, mixing, polyol introduction, temperature control (240-260°C), cooling to 200°C, azeotropic distillation, sample checking for polymerization, and transfer to a dilution blender through a filter for final blending based on solid content.

Advantages

- •Alkyd resin is versatile.

- •Available at low cost.

- •Good weathering property.

- •Alkyd made with non-drying oil, or their fatty acid has excellent color gross stability.

- •Good compatibility with many polymers.

- •Due to its solid nature and reduced solvent vapor emission, it is environmentally friendly.

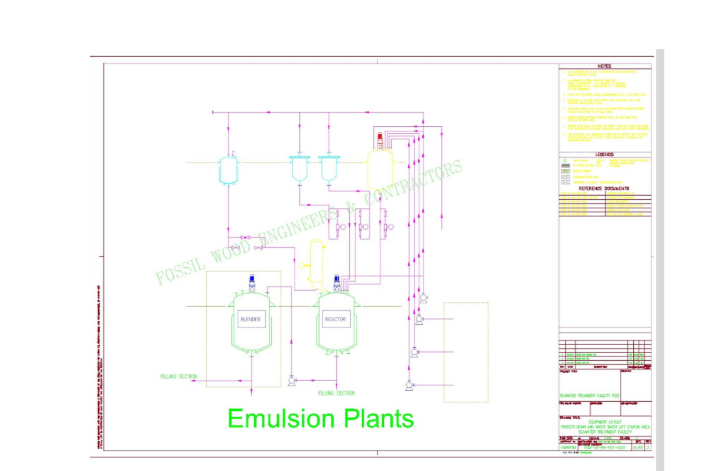

Emulsion Plants

Brief Process:

Water is added in the reactor along with additives and emulsifiers and heated up to approximately 80°C. A stable emulsion is prepared in the monomer tank by mixing water, additives, and monomer. The monomer is added into the reactor along with the catalyst and/or activator. The product is processed in the reactor for 2-3 hours and then cooled to room temperature. Additives are added to get the desired pH, solid content, and viscosity.

Advantages

- •Single source responsibility for complete plant design right from civil-mechanical-electrical to chemical process.

- •Client's scope of work limited to bare minimum.

- •Know-how and training based on years of manufacturing experience.

- •Modern laboratory set up to meet international specifications.

- •Plant design complies with international standards and safety features.

- •Reduced manpower requirement.

Process & Quality Control

Alkyd Resin Manufacturing

Our alkyd resin manufacturing process utilizes advanced reactor technology with precise temperature control (240-260°C) and automated catalyst addition systems. The process includes azeotropic distillation for optimal polymerization control.

The manufacturing process ensures consistent quality through continuous monitoring and automated sampling systems. Final products are filtered and blended according to specific solid content requirements.

Water-Based Emulsions

Our water-based emulsion technology produces high-quality products for paints, coatings, textiles, and adhesives. The process ensures excellent stability and performance characteristics.

Advanced emulsification techniques and quality control systems guarantee consistent product performance across various applications and environmental conditions.