Lube Oil Blending Plants

State-of-the-art modular plant for efficient, high-quality production of automotive and industrial lubricants.

Lube Oil Blending Plants

Comprehensive equipment and technology for manufacturing automotive lubricants, industrial lubricants, synthetic lubricants, bio-based lubricants, marine lubricants, and additive packages.

Capacity ranging from 5MT to 500MT/day.

Lube Oil Blending Plant Overview

Watch our comprehensive lube oil blending system in action, showcasing the complete production process from raw materials to finished lubricants.

Automatic Batch Blenders

Automatic batch blenders are engineered for both simple and intricate formulations, with batch capacities ranging from 5 MT to 200 MT per shift. The automated system doses base oils and additives from storage tanks into blenders equipped with load cells.

A header line with automated valves and instruments provides precise control. Additives are introduced via a drum decanting unit or a batch dosing system. Thorough blending and heating according to a recipe management system, with recirculation until quality standards are met.

- High level of blend flexibility.

- Products can be tailor-made to customer orders.

- Negligible wastage and bottom slop.

- Quick switchover of batches.

- Capacity from 5MT- 200 MT/shift.

Simultaneous Blending Units (SBUs)

Simultaneous blending units (SBUs) are designed for the efficient blending of large quantities of product within short timeframes. All raw materials are pumped from dedicated storage tanks into the system. SBUs combine the advantages of inline blending (ILB) systems and the flexibility of automated batch blending (ABB) systems. These units are skid–mounted and include flow control valves, meters, and various instruments. Base oils and additives are organized into loops based on specific formulations and are passed through a series of headers in precise and controlled ratios. The blended output from the SBU skid is then directed to a storage tank equipped with an agitator to complete the final blending process. To prevent cross-contamination, a pigging system is employed to clean the pipelines and redirect any residual traces of previous batches into designated residual tanks. The product stored in these residual tanks can be utilized in future batches, ensuring minimal waste. The entire operation is automated and managed via a PLC–controlled system, featuring a SCADA interface with Wi-Fi based remote access and cloud data backup capabilities. An MCC (motor control center) is included for managing all installed motors and VFD (variable frequency drive) units. Additionally, automated filling lines can be integrated into the system, providing comprehensive solutions for capping, sealing, labeling, printing, palletizing, and case packing. This ensures a seamless and efficient packaging process.

System Components

- Skid-mounted design: Compact, modular construction for easy installation and maintenance

- Flow control valves: Precise control over material flow rates

- Advanced metering: High-precision flow meters for accurate dosing

- Instrumentation: Comprehensive monitoring and control systems

Blending Process

The SBU process involves:

- Raw materials (base oils and additives) pumped from dedicated storage tanks

- Materials organized into loops based on specific formulations

- Precise ratio blending through header systems

- Blended output directed to storage tanks with agitators for final blending

Waste Management & Cross-Contamination Prevention

- Pigging system: Automated pipeline cleaning to remove residual traces

- Residual redirection: Cleaned materials sent to designated residual tanks

- Waste minimization: Residual materials can be utilized in future batches

- Cross-contamination prevention: Ensures product purity and quality

Automation & Control

- PLC-controlled system: Advanced programmable logic controller for precise operation

- SCADA interface: Supervisory control and data acquisition for real-time monitoring

- Wi-Fi remote access: Secure wireless connectivity for remote operation

- Cloud data backup: Automated data storage and backup systems

- Motor Control Center (MCC): Centralized motor management system

- Variable Frequency Drive (VFD): Energy-efficient motor speed control

Packaging Integration

Automated filling lines can be integrated for comprehensive solutions including:

- Capping and sealing systems

- Automated labeling and printing

- Palletizing and case packing

- End-to-end packaging process automation

Advantages

- High throughput: Efficient processing of large volumes

- Short setup time: Quick changeover between different formulations

- System compatibility: Can be coupled with ABB and ILB systems

- Reduced infrastructure: Fewer dosing modules and blend tanks required

- Flexible capacity: Range from 5MT to 80 MT/hr

- Waste reduction: Minimized product loss through advanced pigging

- Quality assurance: Consistent product quality through precise control

System Architecture Overview

Storage Tanks

Dedicated tanks for base oils and additives with automated transfer systems

Blending Skid

Skid-mounted blending unit with multiple vessels and precision control

Product Storage

Finished product tanks with agitators for final blending and quality assurance

Packaging Lines

Automated filling, capping, labeling, and palletizing systems

120MT Lube Oil Blending Plant

Overview

Fossil Wood Engineering offers a state-of-the-art 120 metric tons (MT) lube oil blending plant, designed for efficient and high-quality production of automotive and industrial lubricants. Our modular and scalable design ensures consistent product quality, operational flexibility, and compliance with international standards.

Key Features

- Blending capacity: 120 MT/day with provisions for multi-grade oil blending

- Batch & inline blending: Advanced blending systems to suit product types and production volumes

- Additive dosing systems: Precision metering for optimal additive incorporation

- Energy-efficient heating: Steam or thermic fluid systems with high-efficiency heat exchangers

- Automated control panel: PLC/SCADA based automation for seamless process control

- Storage & transfer: Dedicated tanks with agitators, transfer pumps, and pipelines for base oil, additives, and finished products

- Filtration system: Inline filtration ensures clean, particle-free finished lubricants

- Filling & packaging: Integrated solutions for drum, pail, and small container filling lines

- Safety & compliance: Explosion-proof instrumentation, fire safety systems, and environmental protection measures

Technical Specifications

| Parameter | Specification |

|---|---|

| Daily Capacity | 120 MT/day |

| No. of Blending Vessels | 4-12 Vessels (Customizable) |

| Heating System | Thermic Fluid / Steam |

| Automation Level | Semi-Automatic / Fully Automatic |

| Additive Tanks | Stainless Steel, Metered Dosing |

| Product Types | Engine Oil, Gear Oil, Hydraulic Oil, Transmission Fluid, etc. |

Applications

Our lube oil blending plants cater to a wide range of industries including:

- Automotive lubricants

- Industrial oils

- Marine oils

- Specialty lubricants

Why Choose Us?

- Custom-built solutions tailored to your production scale and product portfolio

- Turnkey project delivery from design, fabrication, installation to commissioning

- After-sales support including training, maintenance, and upgrades

- International standards: designed to meet API, SAE, and ISO lubricant standards

In-Line Blending (ILB) Systems

In-line blending (ILB) systems are employed to blend large batches that necessitate consistent quality, often packaged in bulk tankers, storage tanks, or totes for shipping.

- Large volume blending.

- Quick turnaround time.

- Direct filling into tankers.

- Consistent quality.

- Capacity from 25MT to 100 MT/hr.

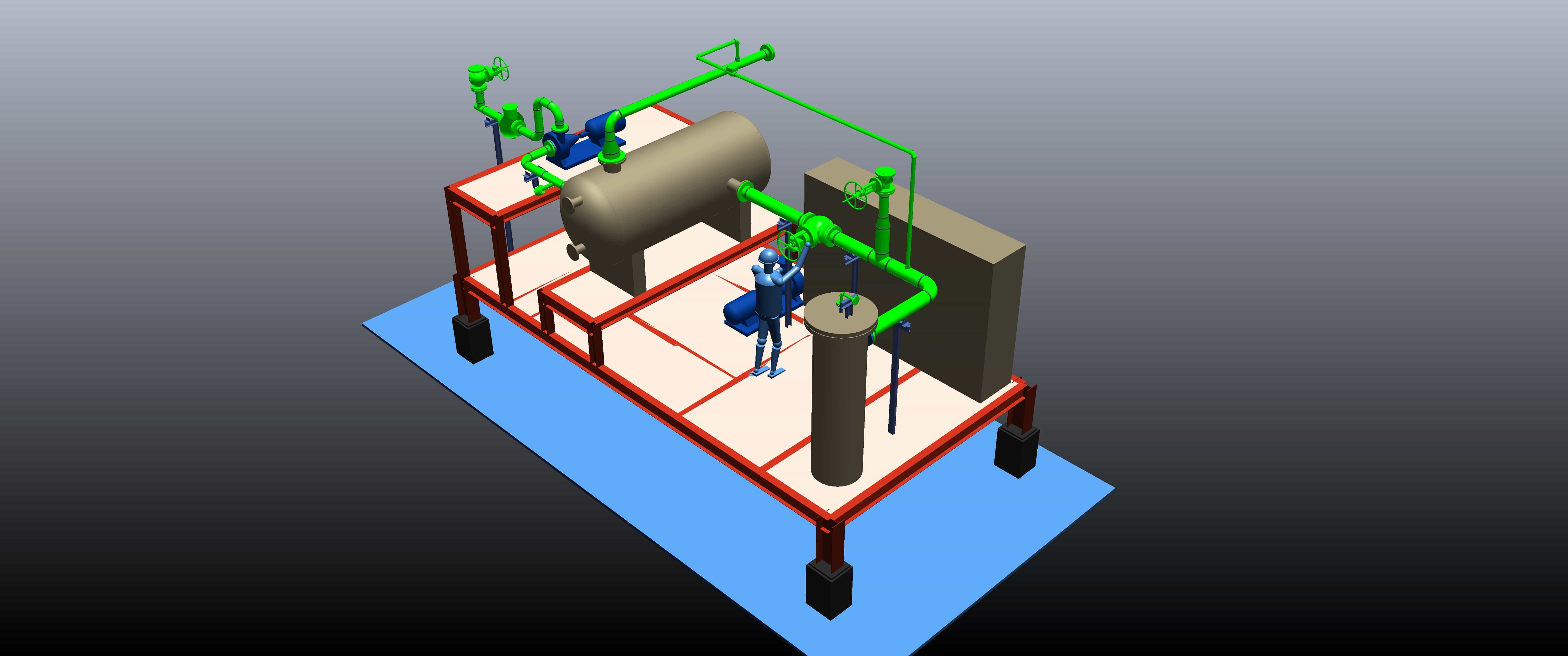

Skid Mounted Plants

Developed by Fossil Wood Engineering, these ABB (automatic batch blending) skid-mounted and containerized plants are designed for companies entering the lubricant business.

- Short delivery and installation time.

- Quick and homogeneous blends.

- Connects directly to flexitanks.

- Low investment costs.

- Reduced on-site erection and hook-up time.

Filling Lines

Our range of filling lines spans from single-head to 16-head linear filling stations, equipped with high-precision flow meters that ensure drip-free operation.

Barrel filling lines

We offer both single and multiple barrel filling stations, designed to accommodate standard containers ranging from 50 to 210 liters.

Pigging Units

Pigging units are critical components in pipeline systems designed to efficiently remove residual products and prevent cross-contamination between different fluids.

- Fewer production lines required.

- Enhanced product quality and yield.

- Prevents cross-contamination between base oils and additives.

- Lowers cleaning expenses.

- Minimizes waste generation.

Drum Decanting Units

Drum decanting units are crucial for precise dosing and transferring liquid additives from various containers (barrels, totes, intermediate bulk containers - IBCs) into blenders or premix tanks.

- High-capacity blending for large volumes.

- Fast processing and turnaround times.

- Direct transfer into tankers for efficiency.

- Uniform and consistent product quality.

- Flexible capacity range from 25 MT to 100 MT per hour.

Automation & Cloud Management

The "FE Intel Plant Automation System" is meticulously designed to optimize productivity and enhance operational efficiency.

- Real-time monitoring and control of formulations.

- Comprehensive production data tracking.

- Raw material usage and inventory management.

- Breakdown and stoppage reporting.

- Analysis of overall plant efficiency.

Laboratory Instruments & Quality Control

Our comprehensive laboratory equipment package includes all essential instruments required for quality control and product testing in lubricant manufacturing.

- Viscosity testing equipment.

- Flash point and pour point analyzers.

- Acid number and base number testers.

- Color and appearance testing instruments.

- Density and specific gravity meters.

Our Advantages

- Custom-built solutions tailored to your production scale and product portfolio

- Turnkey project delivery from design, fabrication, installation to commissioning

- After-sales support including training, maintenance, and upgrades

- International standards: designed to meet API, SAE, and ISO lubricant standards

Essential Utilities

We provide all essential utilities needed to operate the plant, minimizing the client's responsibilities to the greatest extent possible. All utilities required for operating the plant are offered by us to keep the client's scope to the bare minimum.