VI Blending Plants, Modular Viscosity Index Improver & DayAdBlue Plants

Advanced modular viscosity index improvers and diesel exhaust fluid production solutions for modern industrial applications.

VI Blending & AdBlue Plants

Fossil Wood Engineering Services introduces comprehensive modular plant and technology solutions for Viscosity Index Improvers (VII) and Diesel Exhaust Fluid (DEF) production. Our modular design emphasizes flexibility, scalability, and high performance, making it suitable for both small-scale and large-scale industrial applications.

VI Blending Plants

Capacity: 1,000-50,000 LTRS/DAY

DayAdBlue Plants (DEF)

Capacity: 1,000-10,000 LTRS/DAY

VI Blending Plants - Viscosity Index Improvers

Fossil Wood specializes in providing comprehensive plant and technology solutions for Viscosity Index Improvers (VII) production. VII are polymer-based compounds that are crucial for maintaining lubricant viscosity across temperature shifts, preventing thinning at elevated temperatures, and safeguarding equipment integrity.

These compounds facilitate multi-grade oils and streamline maintenance procedures. Our solutions enhance lubricant performance, prolong equipment lifespan, reduce maintenance costs, and enable industries to achieve peak operational efficiency and reliability in diverse environmental conditions.

Key Benefits

Technical Specifications

- Capacity: 1,000-50,000 LTRS/DAY

- Type: Polymer-based compounds

- Application: Multi-grade lubricants

- Technology: Advanced blending systems

DayAdBlue Plants (DEF) - Diesel Exhaust Fluid

Diesel Exhaust Fluid (DEF), dubbed as AUS 32 and marketed under the brand AdBlue, plays a crucial role in curbing harmful emissions from diesel engines in automobiles and heavy vehicles. DEF is injected into the exhaust system to diminish NOx (Nitrogen Oxides) via an SCR catalyst, converting it into harmless nitrogen and water vapor.

This process is crucial for meeting stringent Euro 6 emission standards and significantly reduces NOx by over 95%. DEF is indispensable for modern diesel engines in various applications, including passenger cars, trucks, heavy-duty equipment (tractors, excavators), trains, and maritime vessels. Typical DEF consumption is 5 liters for every 100 liters of diesel consumed.

Key Benefits

Technical Specifications

- Capacity: 1,000-10,000 LTRS/DAY

- Consumption: ~5L per 100L diesel

- Emission Reduction: Over 95% NOx reduction

- Standards: Euro 6 emission compliance

Advanced Modular Design Features

Our modular design emphasizes flexibility, scalability, and high performance. The plant is designed with sustainability in mind, incorporating energy-efficient technologies and waste-minimizing strategies to reduce environmental impact and maximize resource utilization.

Key Components

Reactors

Advanced chemical processing units

Mixers

High-efficiency blending systems

Distillation Units

Precise separation technology

Filtration Systems

Advanced purification processes

Automation & Quality Assurance

Advanced process automation and control systems monitor every step from raw material handling to final packaging, ensuring consistency and precision. The plant adheres to stringent quality standards and regulatory requirements, ensuring each batch meets high specifications.

- Stringent quality standards compliance

- Regulatory requirements adherence

- High specification batch production

- Consistent precision monitoring

Essential Plant Components

Our plants incorporate essential components and practices that form the backbone of modern plant operations, ensuring efficiency, quality control, and seamless production processes.

Blenders

High-efficiency mixing systems

Filters

Advanced filtration technology

Heating Units

Precise temperature control

Filling Stations

Automated packaging solutions

PLC & SCADA

State-of-the-art automation

MCC

Motor control centers

Pumps & Pipelines

Efficient material handling

Advanced Instrumentation

Real-time monitoring

Advanced Technologies

AI-Driven Predictive Maintenance

Enhanced reliability and minimized downtime through intelligent monitoring systems.

Remote Monitoring

Real-time oversight and control capabilities for optimal plant performance.

Sustainability & Eco-Friendly Practices

Our holistic approach focuses on sustainability, including water recycling systems and energy-efficient equipment. This approach benefits the environment, saves costs, and ensures regulatory compliance, making these plants industry leaders in both innovation and responsible production.

Water Recycling Systems

Sustainable water management and conservation practices

Energy-Efficient Equipment

Optimized power consumption and reduced carbon footprint

Regulatory Compliance

Meeting environmental standards and industry regulations

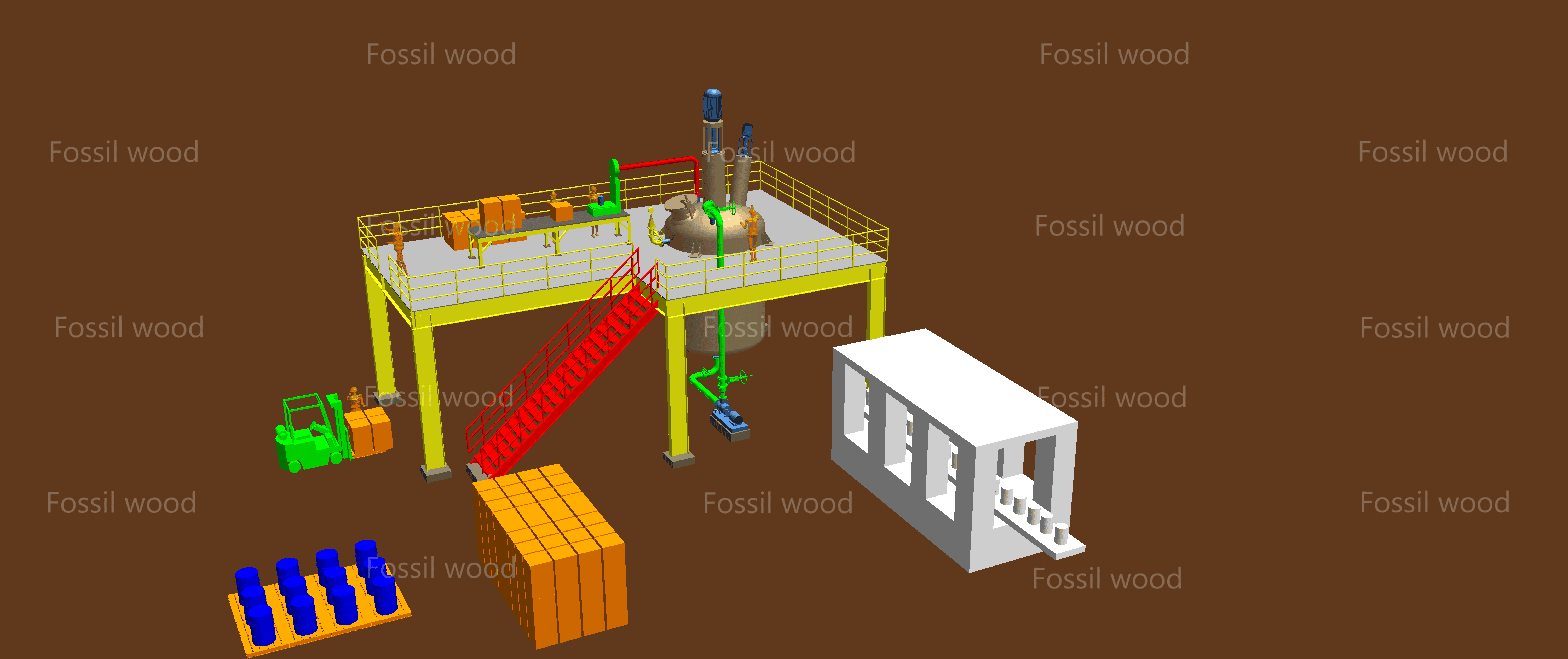

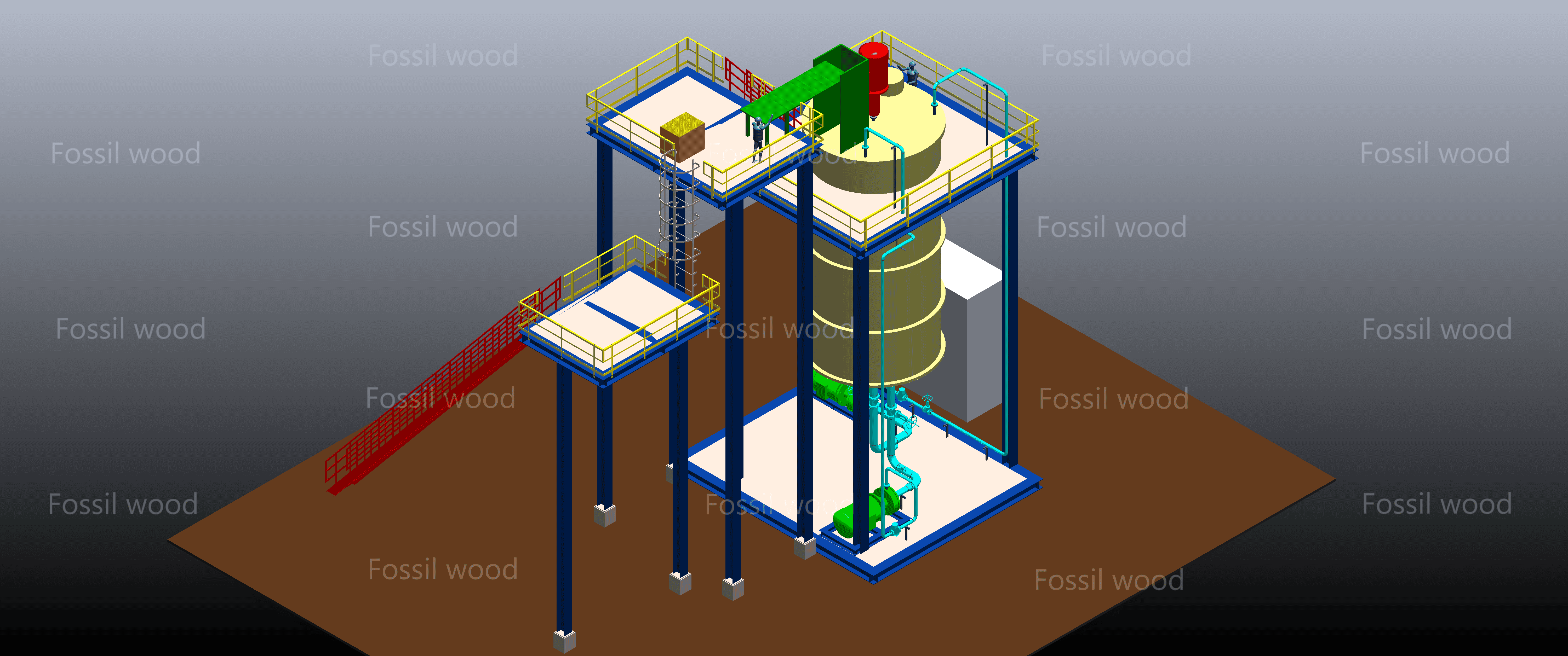

MODULAR VISCOSITY INDEX IMPROVER, LUBRICANT MFG PLANT

Fossil Wood Engineering Services introduces its innovative modular viscosity index improver manufacturing plant, designed to meet the evolving demands of the lubricant industry. The modular design offers flexibility, scalability, and high performance, making it an ideal solution for both small-scale and large-scale lubricant oil blending plants.

This plant is built with cutting-edge technology to ensure optimal production efficiency and superior product quality, while also offering ease of customization and rapid deployment to adapt to market needs.

Advanced Plant Components & Technology

The plant's key components, such as reactors, mixers, distillation units, and filtration systems, are integrated in a way that promotes seamless operation and expansion. With advanced process automation and control systems, every step of the manufacturing process, from raw material handling to final packaging, is meticulously monitored to ensure consistency and precision.

Furthermore, the plant is designed with sustainability in mind, incorporating energy-efficient technologies and waste-minimizing strategies to reduce environmental impact while maximizing resource utilization.

Key Components

Reactors

Advanced chemical processing units

Mixers

High-efficiency blending systems

Distillation Units

Precise separation technology

Filtration Systems

Advanced purification processes

Quality Assurance & Standards

Our modular viscosity index improver manufacturing plant adheres to stringent quality standards and regulatory requirements, ensuring that each batch of viscosity index improver meets the highest specifications.

- Stringent quality standards compliance

- Regulatory requirements adherence

- High specification batch production

- Consistent precision monitoring

Comprehensive Benefits & Future-Ready Solutions

Whether you are entering the viscosity index improver market or looking to expand your production capacity, our plant offers unmatched efficiency, reliability, and adaptability.

Embrace the future of lubrication technology with a plant designed for enhanced performance, reduced operational costs, and improved longevity of machinery and equipment.

Market Entry & Expansion

- Ideal for new market entrants

- Scalable production capacity

- Rapid deployment capabilities

- Customizable to market needs

Performance & Efficiency

- Enhanced operational performance

- Reduced operational costs

- Improved equipment longevity

- Unmatched reliability