Waste Oil to Diesel Plant

Advanced pyrolysis distillation technology for converting waste oils into sustainable diesel fuel.

Advanced Pyrolysis Technology

Our waste oil to diesel plant utilizes cutting-edge pyrolysis distillation technology to efficiently convert various types of waste oils into high-quality diesel fuel that meets international standards.

The process involves sophisticated thermal decomposition under controlled conditions, followed by advanced refining steps to ensure the final product meets all quality and environmental requirements.

Waste Oil to Diesel Plant

A waste oil to diesel plant is a specialized industrial facility aimed at converting waste oils, such as used motor oil or cooking oil, into diesel fuel. The process employed, known as pyrolysis distillation, takes advantage of high heat in the absence of oxygen to break down the complex molecular structures found in waste oils. This thermal decomposition transforms the waste oils into a range of smaller hydrocarbons, which are then refined and processed to produce diesel fuel. The process provides an eco-friendly solution for managing waste oils, which might otherwise end up in landfills or be improperly disposed of.

The operation of a waste oil to diesel plant begins with pre-treatment of the waste oil to remove impurities like water, solids, and contaminants. Once purified, the oil is heated in a reactor vessel to a specific temperature where it undergoes pyrolysis. During pyrolysis, the oil decomposes into volatile gases, which are collected and condensed into liquid form through a cooling process. This liquid, once purified, can be used as a diesel substitute, contributing to reducing the dependency on traditional fossil fuels.

Waste oil to diesel plants represent a significant step toward sustainable energy production. By recycling used oils, they not only provide an alternative source of diesel fuel but also help mitigate the environmental impact of waste oil disposal. This process reduces the volume of waste oil that would otherwise pollute the environment, offering a dual benefit of cleaner energy and waste management. These plants are integral to promoting circular economies, where resources are reused, reducing reliance on new raw materials and fostering a greener, more sustainable future.

- Eco-friendly waste oil management solution

- Reduces reliance on traditional fossil fuels

- Prevents improper disposal and pollution

- Promotes circular economy principles

- Sustainable energy production

- Meets EURO-V emission standards

Application

The FW Waste Oil to Diesel Plant is a cutting-edge solution designed to transform waste motor oil into valuable diesel fuel, offering a sustainable way to recycle and repurpose used oils. By utilizing Fossil Wood's advanced fractionating and ultrasonic desulfuring technologies, the plant is able to crack long-chain hydrocarbons into high-quality diesel that meets EURO-V emission standards. This process not only produces diesel fuel but also generates valuable byproducts such as light gas oil, light hydrocarbons, water, and asphaltene sludge, contributing to both environmental sustainability and economic viability.

This versatile plant is capable of converting a variety of waste oil feedstocks into diesel fuel, including waste motor oil, waste gear oil, waste crankcase oil, waste hydraulic oil, tire/plastic pyrolysis oil, and slop oil. By addressing multiple waste oil types, the FW Waste Oil to Diesel Plant offers a flexible and cost-effective solution to the growing global demand for both sustainable fuel alternatives and waste oil management. It represents a significant advancement in energy recovery and recycling technology, helping businesses optimize their operations and reduce environmental impacts.

In addition to the waste oil to diesel plant, Fossil Wood offers complementary solutions such as the waste oil to base oil plant and lube oil refining plant. These technologies further enhance the profitability and sustainability of businesses by enabling the efficient refining of used oils into valuable base oils and high-quality lubricants. By investing in these innovative technologies, companies can achieve their sustainability goals while simultaneously reducing their operational costs and contributing to the circular economy.

Pre-treatment

Remove impurities like water, solids, and contaminants from waste oil.

Pyrolysis

Heat purified oil in reactor vessel to decompose into volatile gases.

Collection & Condensation

Collect and condense gases into liquid form through cooling.

Diesel Substitute

Purified liquid can be used as diesel substitute fuel.

Working Principle

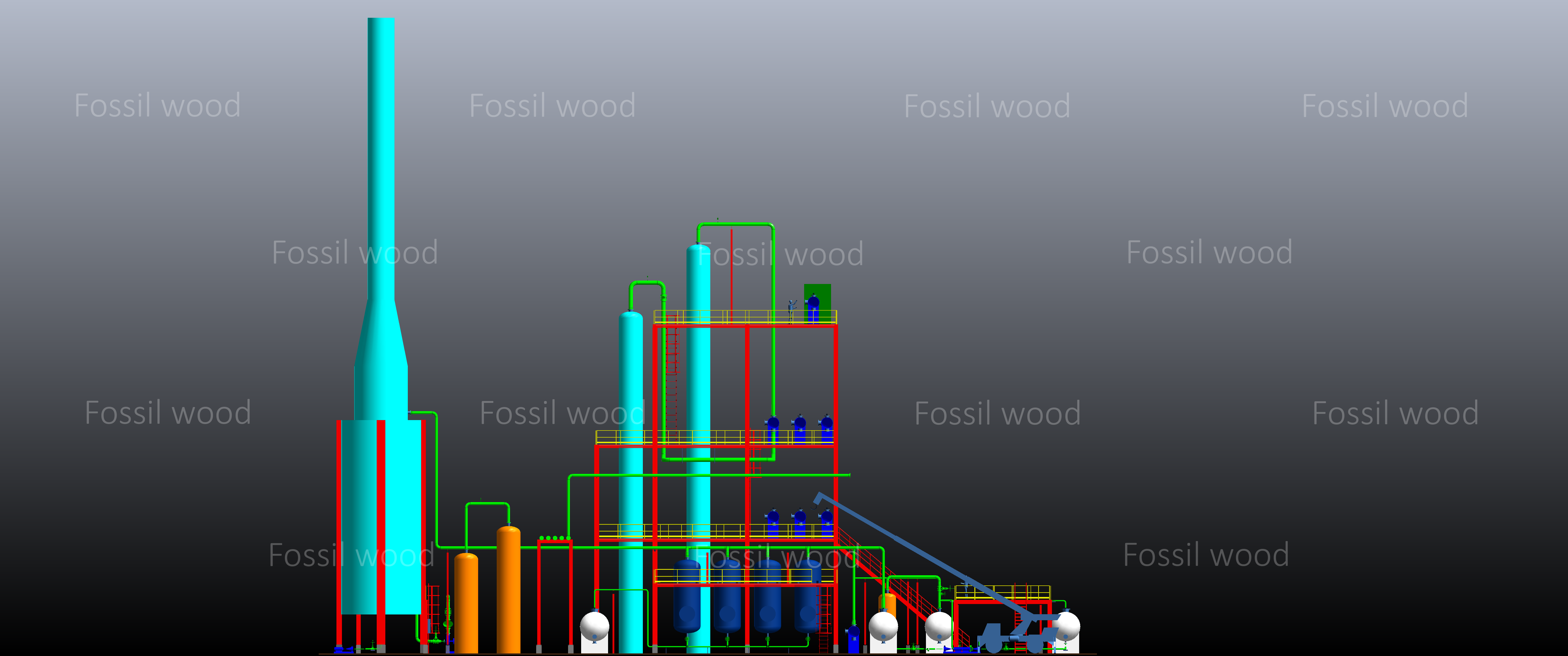

The FW Waste Oil to Diesel Plant has implemented Fossil Wood's distinctive engineering designs, which may include the following systems:

Dehydration & Sedimentation Unit

Removes water and solid impurities from waste oil feedstock.

Light Gas Oil (LGO) Stripping System

Extracts light gas oil components from the process stream.

Fractionation & Reflux System

Advanced separation technology for hydrocarbon fractions.

Integrated Heaters & Heat Exchangers

Efficient thermal management and energy recovery systems.

Diesel Polishing Unit

Final purification to meet EURO-V emission standards.

Advanced PLC/SCADA Control System

Fully automated monitoring and control operations.

Environmental Benefits

Our Waste Oil to Diesel Plant provides comprehensive environmental benefits, promoting sustainable practices and contributing to a greener future:

Waste Reduction

Significantly reduces waste volume and prevents landfill disposal.

Pollution Prevention

Prevents improper disposal and environmental contamination.

Circular Economy

Promotes resource reuse and reduces reliance on new raw materials.

Sustainable Energy

Provides alternative diesel source and sustainable energy production.

Key Features & Technology

Pyrolysis Distillation

High heat process in absence of oxygen for molecular breakdown.

Eco-friendly Solution

Environmentally responsible waste oil management.

Diesel Production

Converts waste oils into usable diesel fuel substitute.

Industrial Scale

Specialized facility for large-scale waste oil processing.

Waste Oil Types Processed

Our versatile plant can convert a wide range of waste oil feedstocks, offering a flexible and cost-effective solution to the growing global demand for both sustainable fuel alternatives and waste oil management:

Waste Motor Oil

Processing automotive waste oils into diesel fuel.

Waste Gear Oil

Converting used gear oils into renewable fuel.

Waste Crankcase Oil

Recycling crankcase oils for fuel production.

Waste Hydraulic Oil

Processing hydraulic oils into diesel fuel.

Tire/Plastic Pyrolysis Oil

Converting pyrolysis oils into usable fuel.

Slop Oil

Processing slop oil into valuable diesel fuel.

By-Products & Complementary Solutions

Products and By-Products

The primary output of this process is oil, with approximately 80% to 85% meeting commercial diesel specifications. Byproducts generated include:

- Light Ends - Used as fuel oil for burners in cement, glass, ceramics, power generation, steel manufacturing, and boiler operations

- Water - Filtered and purified for use as cooling water

- Oil Sludge/Residue - Effectively repurposed for asphalt production and road construction

Complementary Solutions

Fossil Wood also offers complementary solutions that further enhance the profitability and sustainability of businesses:

- Waste Oil to Base Oil Plant

- Lube Oil Refining Plant

- Refines used oils into valuable base oils

- Produces high-quality lubricants

Production Schedule

Our comprehensive production process follows a structured approach to ensure quality, efficiency, and timely delivery:

Project Kick-off Meeting

Initial project planning and requirements gathering.

Design Phase

P&ID development, process simulation, equipment selection, sizing, and heat exchanger calculations.

Manufacturing & Testing

Equipment manufacturing and individual component testing.

Plant Assembly & Testing

Complete plant assembly for comprehensive testing.

Disassembly & Shipping

Plant disassembly for safe transportation to site.

Waste Management & Disposal

Our plant implements comprehensive waste management strategies to ensure environmental responsibility and resource optimization:

Gas Treatment

Treated for emissions or recycled as heating fuel.

Water Filtration

Filtered and purified for use as cooling water.

Oil Sludge Utilization

Used for combustion or as material for asphalt production and road construction.

Extended Information

Detailed answers to frequently asked questions about our Waste Oil to Diesel Plant technology and processes.

1. Products and By-Products

The primary output of this process is oil, with approximately 80% to 85% meeting commercial diesel specifications. Byproducts generated include light ends, water, and oil sludge or residue. The light ends can be used as fuel oil for burners in industries such as cement, glass, ceramics, power generation, steel manufacturing, and boiler operations. Meanwhile, the oil sludge or residue can be effectively repurposed for asphalt production.

2. What's the Production Schedule of SN Order?

The production will commence with a project kick-off meeting, followed by the design phase, which includes P&ID development, process simulation, equipment selection, sizing, and heat exchanger calculations. This will be followed by manufacturing and equipment testing, after which the entire plant will be assembled for testing. Finally, the plant will be disassembled for shipping.

3. Waste Management and How to Dispose Them?

The waste typically consists of gas, water, and oil sludge/residue. The gas will be treated for emissions or recycled as a heating fuel. The water can be filtered and purified for use as cooling water. The oil sludge can be utilized for combustion or as a material for asphalt production or road construction.

4. What is the Quality of Diesel to be Produced by Your Machine?

Our distillation plant produces diesel that meets API standards for commercial diesel, making it suitable for direct use in diesel engines. For more information, please reach out for the test report.

Economic & Environmental Impact

Environmental Impact

- Prevents waste oils from ending up in landfills

- Reduces environmental contamination and pollution

- Promotes sustainable energy production

- Contributes to circular economy principles

Economic Benefits

- Reduces reliance on traditional fossil fuels

- Provides alternative diesel source

- Reduces waste management costs

- Fosters greener, more sustainable future

Technical Specifications

Technology

Fossil Wood FW

Process Type

Fractionating & Ultrasonic Desulfuring

Emission Standards

EURO-V Compliant

Output Yield

80-85% Commercial Diesel

Quality Standards

API Standards Compliant

Sustainability

Circular Economy

Our Advantages

- Fossil Wood's advanced fractionating and ultrasonic desulfuring technologies

- EURO-V emission standards compliance

- 80-85% commercial diesel output yield

- API standards compliant diesel quality

- Comprehensive waste management and disposal

- Structured production schedule for timely delivery