Grease Plants

Complete plant & technology for production of lithium grease, calcium grease, complex grease and non-soap grease

GREASE PLANTS

Complete plant & technology for production of lithium grease, calcium grease, complex grease and non-soap grease

Grease consists of a finely dispersed thickening agent, typically soap, in a lubricating fluid, commonly mineral oil. The soap is derived from fatty acids, tallow, or vegetable oils reacted with alkalis like hydrated lime, caustic soda, lithium hydroxide, or aluminum hydroxide. The primary lubricating oil used is usually Group 1 or Group 2 refined base oil.

Structurally, grease forms a "water-in-oil" emulsion and typically appears smooth, translucent, and can vary in softness or hardness. The essential properties that determine grease performance include structural stability, lubricating ability, and performance across low and high temperatures, which are influenced by the choice of lubricating oil base stock.

Additionally, grease relies on its soap component for properties like water resistance, high-temperature performance, resistance to continuous use breakdown, and adherence to surfaces. To tailor grease for specific applications, various additives such as graphite, modified clay, asphalt, oxidation & corrosion inhibitors, extreme pressure additives like molybdenum disulphide, are incorporated.

These additives impart specialized properties required for diverse end-use scenarios.

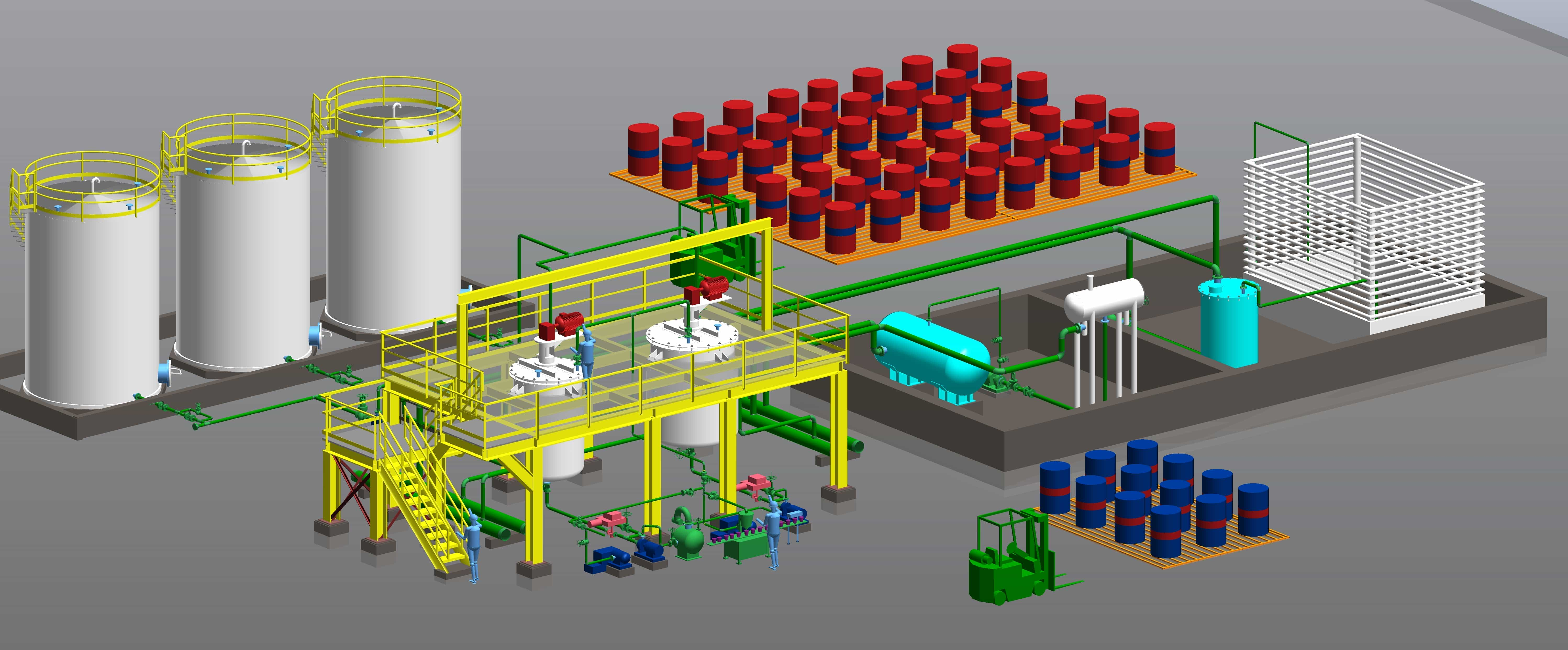

Grease Plant Overview

Watch our comprehensive grease manufacturing system in action, showcasing the complete production process from raw materials to finished grease products.

ADVANTAGES

- Pressure Kettle

- Atmospheric Kettle

- Holding Kettle

- Milling and Deaeration

- Skid Mounted Grease Plant

- Lab Grease Plant/Pilot Plant

- Homogeniser

- Packing and Filling

- Automation

- Utilities

- Lab Instruments

Grease Properties & Performance

Essential Properties

The essential properties determining grease performance include structural stability, lubricating ability, and performance across low and high temperatures, all influenced by the choice of lubricating oil base stock.

The soap component plays a crucial role in properties like water resistance, high-temperature performance, resistance to continuous use breakdown, and adherence to surfaces.

Additives & Formulations

Various additives are incorporated to tailor grease for specific applications. Examples include graphite, modified clay, asphalt, oxidation & corrosion inhibitors, and extreme pressure additives like molybdenum disulphide.

These additives impart specialized properties for diverse end-use scenarios, ensuring optimal performance in various industrial applications.

Grease Plant

Our comprehensive grease manufacturing solutions offer cutting-edge technology and equipment for efficient production.

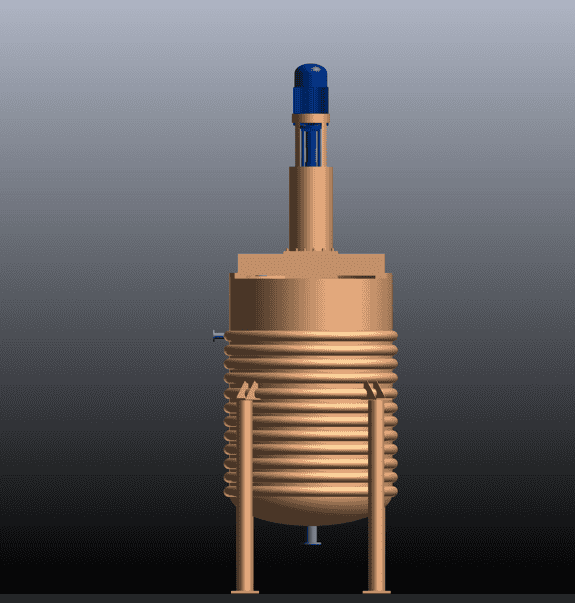

Pressure Kettle

High-pressure processing for efficient grease production.

Atmospheric Kettle

Standard atmospheric processing units.

Holding Kettle

Storage and holding tanks for processed grease.

Milling and Deaeration

Particle size reduction and air removal systems.

Skid Mounted Grease Plant

Compact, transportable grease production units.

Lab Grease Plant/Pilot Plant

Small-scale testing and development facilities.

Homogeniser

Uniform mixing and consistency control.

Packing and Filling

Automated packaging and filling systems.

Automation

Advanced control and monitoring systems.

Utilities

Essential support systems and infrastructure.

Lab Instruments

Quality control and testing equipment.

Pressure & Holding Kettles

Advanced industrial kettles engineered for efficient grease and soap production under controlled conditions.

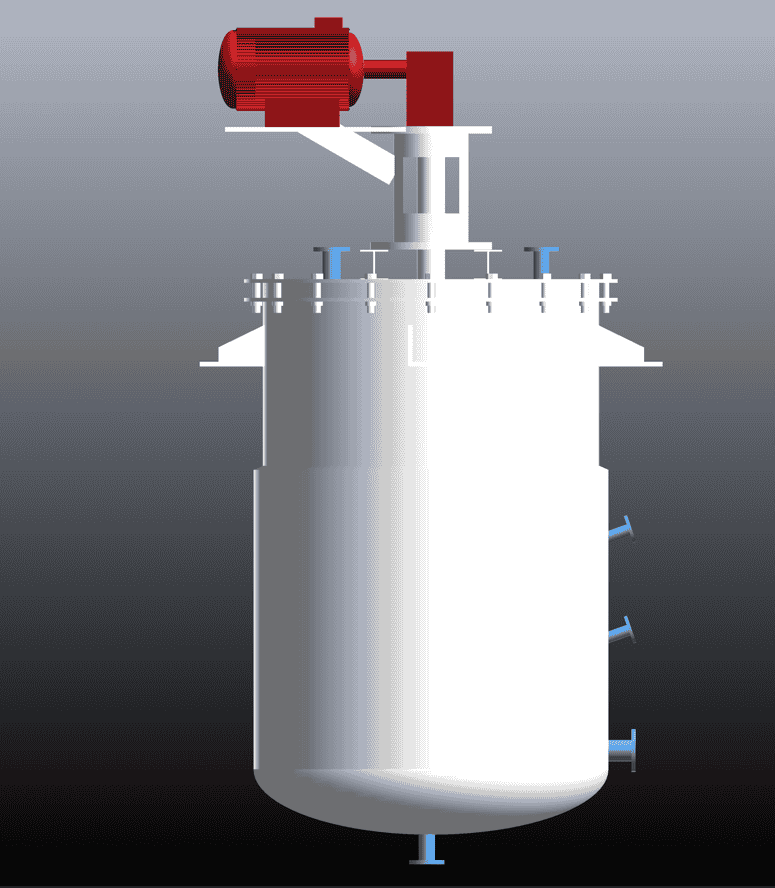

PRESSURE KETTLE

Pressure vessels are engineered specifically for the production of soaps under extreme pressure and temperature conditions. Their unique contra-rotary agitator assembly, coupled with rapid heating, significantly reduces saponification time. This not only enhances productivity but also boosts the quality of the end product.

By operating under pressure, these vessels increase the yield per kg of soap used, resulting in a more efficient production process. The homogeneous mixture produced in these kettles is free of lumps, ensuring a consistent and high-quality output. Batch times typically vary between 3 to 4 hours, depending on the type of grease being processed and its specific formulation.

These vessels are equipped with load cells for precise measurements and feature header lines with automated valves, gauges, instrumentation, and safety valves, all integrated with a PLC for seamless control and monitoring. In addition to traditional soap varieties, such as those made from lithium, calcium, aluminium, urea, and complex greases, these vessels can accommodate a wide range of formulations, further expanding their versatility and applicability in soap manufacturing processes.

ADVANTAGES

- ✓HIGHER PRODUCTIVITY

- ✓IMPROVED QUALITY

- ✓POWER AND COST SAVING

- ✓CAPACITY: BATCH SIZE RANGING FROM 100-5000 KGS

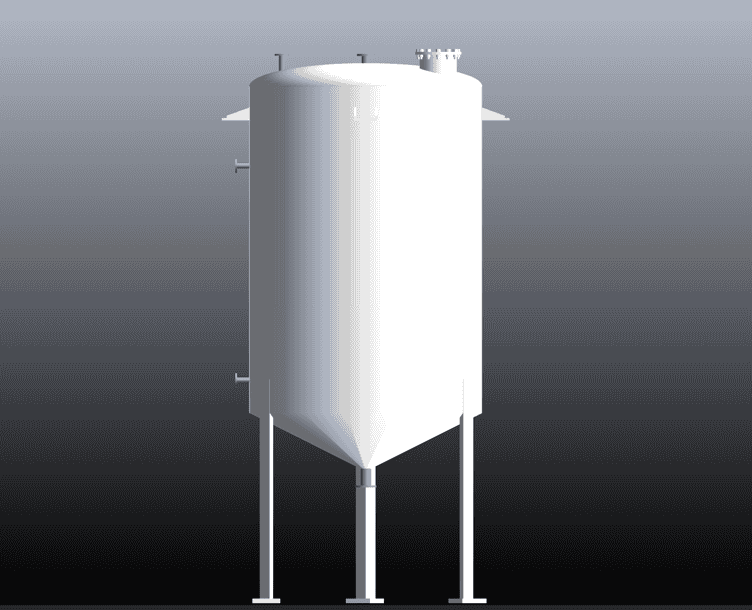

HOLDING KETTLE

Grease finishing involves transferring the final products to specialized holding kettles for temporary storage before they are packaged into barrels or smaller containers. This setup not only facilitates a continuous production flow by freeing up the finishing kettle for the next batch but also streamlines the filling process, which may typically take anywhere from 1 to 3 hours.

These holding kettles are intricately connected to the filling lines, designed with proper jacketing and insulation for optimal temperature control. Additionally, they can be equipped with load cells and seamlessly integrated into automated systems for enhanced efficiency if needed. This meticulous arrangement ensures smooth operations and consistent quality in grease production.

ADVANTAGES

- ✓INCREASES PLANT CAPACITY

- ✓FLEXIBILITY IN FILLING

- ✓NO PRODUCT CONTAMINATION

- ✓CAPACITY FROM 100-10000 KGS

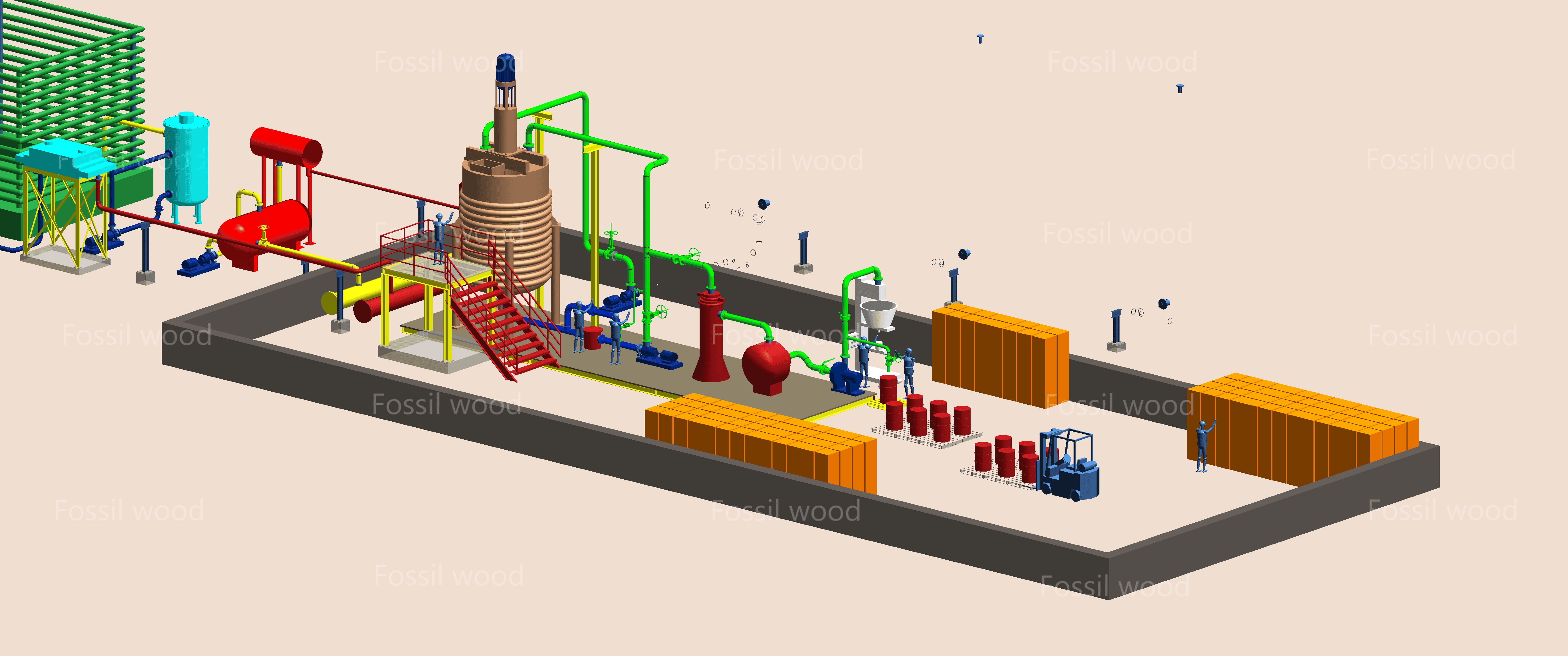

GREASE USING SINGLE UNIVERSAL KETTLE

Advanced finishing kettles designed for crafting final grease at standard atmospheric pressure and temperature.

FINISHING KETTLES

Finishing kettles, significantly larger than pressure kettles, are tailored for crafting the final grease at standard atmospheric pressure and temperature. These specialized kettles facilitate the blending of base oils and additives, followed by a cooling process, recirculation, and passage through homogenizers or milling systems as necessary.

The agitator assembly's contra-rotary design ensures a uniform texture, devoid of air pockets or clumps, delivering the desired quality. Depending on the grease type and formulation, batch durations typically span 3 to 4 hours. These kettles boast load cell mounts, alongside header lines equipped with automated valves, gauges, and instrumentation, all integrated with a PLC for seamless control.

They are adept at producing a variety of greases including those derived from lithium, calcium, aluminium, urea, and complex formulas.

ADVANTAGES

- ✓HIGHER PRODUCTIVITY

- ✓IMPROVED QUALITY

- ✓POWER AND COST SAVING

- ✓CAPACITY: BATCH SIZE RANGING FROM 100-5000 KGS

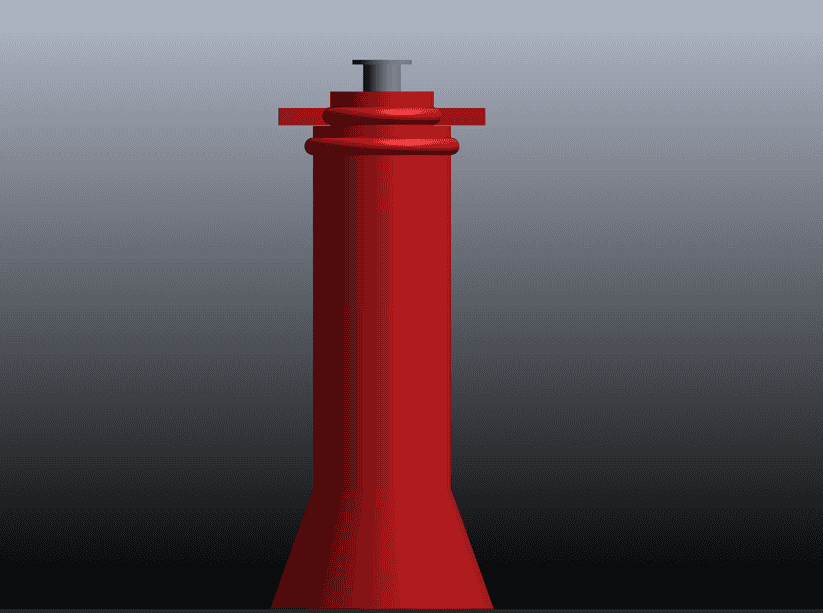

MILLING & DEAERATION

The processing of grease in the finishing kettle often leads to the entrapment of large volumes of air or gas, which can have negative impacts on the final product.

Process Overview

These effects may include changes in color, increased rancidity, oxidation, and inaccurate weight distribution upon settlement. Implementing efficient milling and deaeration systems significantly enhances the quality of the grease output. The texture, drop point, and penetration of the final product rely heavily on the effectiveness of these systems.

Milling Machine Mechanism

The heart of the milling machine lies in its rotor and stator mechanism, both crafted from durable cast special steel designed to endure rigorous wear and tear. As the material passes through the gap between the stator and rotor, it undergoes substantial shearing forces before exiting the mill.

The precision in controlling the gap between these components allows for adjustments in product rate and fineness even during operation.

Deaeration Chamber

Moving to the deaeration chamber, it features an enclosed vacuum steel chamber housing a high-speed centrifugal disc. Upon introduction of grease into this chamber, it spreads across the rotating disc.

The combined action of centrifugal force and vacuum pressure within the chamber effectively eliminates trapped air, which is then expelled through the vacuum outlet. The purified grease is subsequently collected and directed towards the discharge outlet.

Critical Components

Critical components of this system include the feed manifold, feed & discharge pumps, load cell mounted blenders, additive dosing unit, heating unit, online filters, piping, valves, instrumentation, and filling station. These elements operate seamlessly through a semi-automatic PLC system integrated with HMI controls, ensuring a streamlined and efficient production process.

ADVANTAGES

- ✓Improved quality

- ✓Improved texture with glossy appearance

- ✓Better shelf life

- ✓Precise packing

- ✓Batch size ranging from 1000-50000 KGS/HR

- ✓Reduced on-site erection and hook-up time

- ✓Factory tested and manufactured

- ✓Single source responsibility, ensuring fewer interfaces for the client to handle

- ✓Self-contained operations

- ✓Manufactured to CE specifications

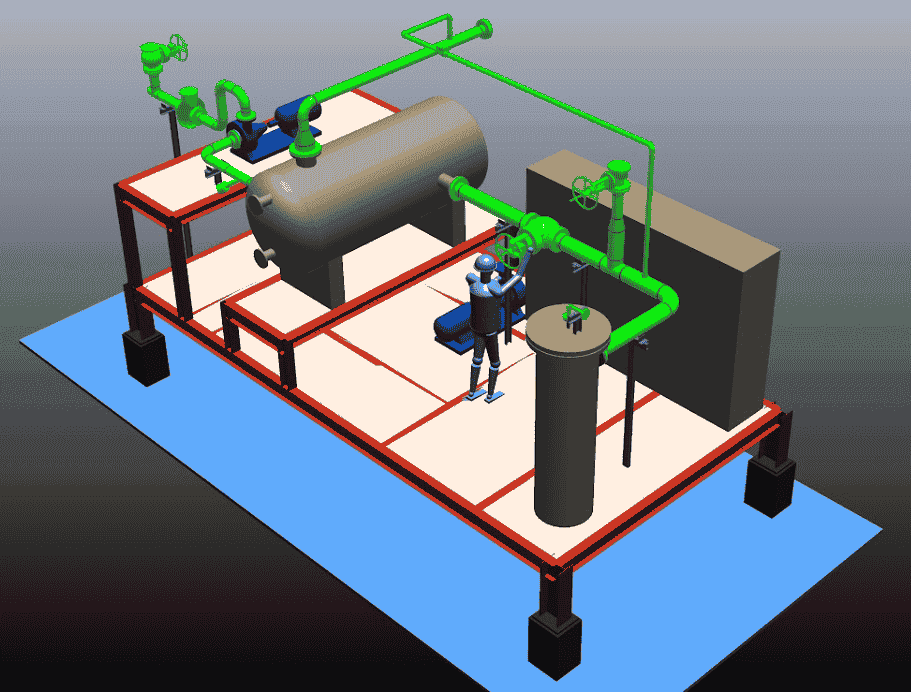

SKID MOUNTED GREASE PLANT

Tailored for small-scale batches, ideal for companies entering the grease business and suited for remote or challenging logistical settings.

Turnkey Solution

Our skid mounted grease plants offer versatility for indoor and outdoor installations, with an optional generator connection for autonomy. These are turnkey solutions, rigorously assembled and tested, arriving in 20 or 40 ft containers, eliminating on-site assembly, pipework, electrical wiring, or component mounting.

The system provides seamless plug-and-play functionality and integration of base oils from flex tanks. Each package includes essential laboratory testing equipment, spares, maintenance tools, and a starting formulations booklet.

Key Components

Critical components include feed manifold, feed & discharge pumps, load cell mounted kettles, heating unit, online filters, piping, valves, instrumentation, and a filling station, all seamlessly interconnected and operated via a semi-automatic PLC system with HMI controls.

End-users simply connect base oils from flex tanks to the feed manifold, and a quick change-over flushing system enables rapid product turnarounds.

Versatile Production

The plants are versatile, capable of producing various grease types including Lithium, Calcium, Chassis, Complex, Non-Soap, Specialty Grease, and Food Grade Grease. Know-how and starting formulations are offered on request to ensure seamless integration and productivity.

ADVANTAGES

- ✓SHORT DELIVERY AND INSTALLATION TIME

- ✓QUICK AND HOMOGENEOUS BLENDS

- ✓CONNECTS DIRECTLY TO FLEX TANKS

- ✓LOW INVESTMENT COSTS

- ✓REDUCED ON-SITE ERECTION AND HOOK-UP TIME

- ✓FACTORY TESTED AND MANUFACTURED

- ✓SINGLE SOURCE RESPONSIBILITY, ENSURING FEWER INTERFACES FOR OUR CLIENT TO HANDLE

- ✓SELF-CONTAINED OPERATIONS

- ✓MANUFACTURED TO CE SPECIFICATIONS

LAB GREASE PLANT

Designed specifically for producing small batches of grease, ranging from 50 to 100 kgs per batch, perfect for research, development, and pilot production.

Fossil Wood Lab Grease Plants

Fossil Wood presents its lab grease plants designed specifically for producing small batches of grease, ranging from 50 to 100 kgs per batch. Our pilot plants feature a state-of-the-art universal pressure kettle with a contra rotary agitator and scraper, ensuring efficient saponification and high-quality finished grease production. Upon request, we can also provide a separate kettle for finishing purposes.

Our skid-mounted plant comes fully equipped with a heating and cooling unit, milling machine, filter, vacuum and gear pumps, all integrated with piping, valves, and instruments for seamless operation.

Advanced Control System

Our control panel boasts a variable frequency drive (VFD) for precise control over agitator speed, user-friendly push-button stations, temperature controller, and an energy meter to monitor process efficiency and productivity. Additionally, a data logger is installed in the panel to record product temperature and pressure over time, ensuring accuracy and quality consistency.

Installation & Setup

The entire plant is designed to be mounted on a skid and requires installation on a leveled concrete surface, providing stability and optimal performance.

ADVANTAGES

- ✓SHORT DELIVERY AND INSTALLATION TIME

- ✓QUICK AND HOMOGENEOUS BLENDS

- ✓CONNECTS DIRECTLY TO FLEX TANKS

- ✓LOW INVESTMENT COSTS

- ✓REDUCED ON-SITE ERECTION AND HOOK-UP TIME

- ✓FACTORY TESTED AND MANUFACTURED

- ✓SINGLE SOURCE RESPONSIBILITY, ENSURING FEWER INTERFACES FOR OUR CLIENT TO HANDLE

- ✓SELF-CONTAINED OPERATIONS

- ✓MANUFACTURED TO CE SPECIFICATIONS

Lab Instruments

Explore our comprehensive range of laboratory instruments designed to elevate your quality assurance protocols.

Access our downloadable catalog for a detailed list of instruments tailored to your specific needs. Every project we embark on comes equipped with essential basic instruments, ensuring seamless quality checks at every step. Should your requirements demand it, additional instruments are available for separate purchase, providing you with the flexibility to optimize your laboratory setup and achieve precise results.

Automatic Grease Worker

Industrial machine for automated grease processing and consistency testing.

Cone Penetrometer

Precision device for measuring grease consistency and penetration depth.

Drop Point Apparatus

Vertical apparatus for testing grease drop point and thermal stability.

Lab Furnace

Compact laboratory oven with digital controls for precise temperature testing.

Pan Balance

Digital weighing scale for precise measurement of grease components.

Wheel Bearing Tester

Advanced testing machine for evaluating grease performance in bearing applications.

Quality Assurance Package

Every grease plant project includes essential basic instruments for seamless quality checks. Additional instruments are available for separate purchase to optimize your laboratory setup and achieve precise results.

Grease Manufacturing Process

Processing Equipment

- •Pressure Kettles: High-pressure processing for efficient grease production with precise temperature and pressure control.

- •Atmospheric Kettles: Standard processing units for conventional grease manufacturing.

- •Holding Kettles: Storage and holding tanks for processed grease with temperature maintenance.

- •Milling and Deaeration: Particle size reduction and air removal systems for quality control.

Specialized Systems

- •Skid Mounted Plants: Compact, transportable grease production units for flexible deployment.

- •Lab/Pilot Plants: Small-scale testing and development facilities for new formulations.

- •Homogenisers: Uniform mixing and consistency control for product quality.

- •Automation: Advanced control and monitoring systems for process optimization.

Quality Assurance & Testing

Lab Instruments

Comprehensive testing equipment for quality control and performance validation.

Packing & Filling

Automated packaging and filling systems for consistent product delivery.

Utilities

Essential support systems and infrastructure for optimal plant operation.