Base Oil Solvent Extraction Plant

Advanced technology for cutting-edge base oil purification and contaminant removal.

Base Oil Purification Excellence

Our state-of-the-art Base Oil Solvent Extraction Plant represents the pinnacle of oil purification technology. Using advanced FW processes, we deliver superior quality base oils that meet the most stringent industry standards.

The facility combines innovative extraction methods with precise process control to ensure optimal removal of undesirable compounds while maintaining the essential properties of the base oil.

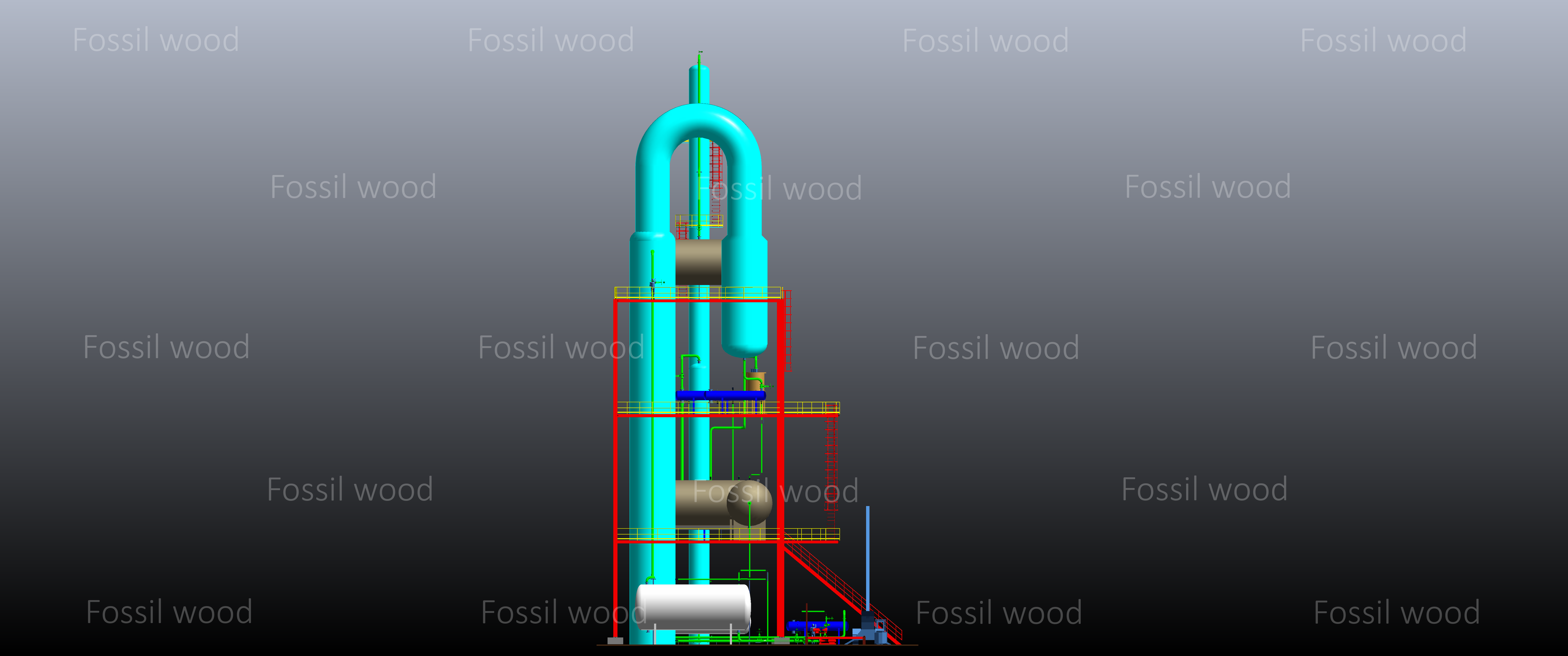

Solvent Extraction Plant

Advanced Base Oil Purification Technology

The FW Solvent Extraction Plant is a cutting-edge solution designed to remove undesirable contaminants from base oils, especially those derived from waste oil refineries. This includes the efficient extraction of harmful compounds such as:

- Polycyclic Aromatic Hydrocarbons (PAHs)

- Gums and Asphaltenes

- Sulfur, Nitrogen, and Oxygen Compounds

These impurities, if left untreated, significantly degrade the performance and stability of base oils.

- Advanced contaminant removal technology

- Efficient extraction of harmful compounds

- Enhanced base oil performance and stability

- Waste oil refinery optimization

- Environmental compliance and safety

- Superior product quality and reliability

Innovative Reverse Extraction Technology

At the core of our system is a continuous reverse solvent extraction column, developed and patented by the Fossil Wood Engineering team. This advanced technology is specifically engineered to:

- Enhance Viscosity Index

- Improve Oxidation Stability

- Reduce Carbon Residue

- Achieve Superior Color and Clarity

By reversing the traditional extraction flow, our system enables higher selectivity and efficiency, especially when processing base oils recovered from used or contaminated oil sources.

98% Recovery Rate

Exceptional yield of Group I+ base oil recovery.

Low Solvent Consumption

Only 1 kg solvent per ton of processed oil.

Continuous Operation

High throughput with uninterrupted processing.

Modular Design

Compact and scalable plant configuration.

High Solvent Recovery

98%+ solvent recovery rates for efficiency.

Improved Oil Properties

Enhanced viscosity index, oxidation stability, and clarity.

Exceptional Yield & Efficiency

Thanks to Fossil Wood's exclusive solvent extraction and recovery innovations, the FW system delivers over 98% recovery of Group I+ base oil, using only 1 kg of solvent per ton of processed oil — setting a new benchmark in environmental sustainability and cost-efficiency.

By-Products with Commercial Value

The process yields two main outputs:

Raffinates (Neutral Base Oils)

High-quality base stocks suitable for use in lubricant blending.

Aromatic Extract Fluid

Rich in aromatic content, this by-product serves as a valuable feedstock for process oils, fuel oils, and rubber compounding applications.

Key Features

Continuous Operation for High Throughput

Environmentally Responsible with Low Solvent Consumption

Modular and Compact Design

Fully Automated with PLC/SCADA Integration

High ROI Through Energy Efficiency and Product Purity

Applications

Waste Oil Re-refining Units

Lube Oil Blending Plants

Petroleum Reprocessing Facilities

Industrial Base Oil Recovery Plants

Core Systems & Features

The FW plant includes integrated systems designed to ensure maximum efficiency and performance, delivering superior product yield while ensuring environmental compliance and operational safety.

Heater & Heat Exchange System

High-efficiency thermal oil heaters and heat exchangers with heat recovery technology.

Multistage Solvent Extraction System

Advanced extraction technology with preheated feedstock for optimal performance.

Base Oil Desolvent System

Vacuum distillation or steam stripping for high-purity end products.

Solvent Recovery System

Closed-loop circulation with minimal solvent loss and operational costs.

Exhaust Purification System

Scrubbers, filters, and activated carbon systems meeting international standards.

PLC/SCADA Control System

Fully automated operations with real-time monitoring and diagnostics.

Commercial Value Outputs

The FW process yields two main outputs with significant commercial value, producing Group I and Group II base oils suitable for blending:

Raffinate (Neutral Oil)

High-purity base stock suitable for blending into a wide range of lubricants.

Extract Fluid

Rich in aromatic content, ideal for process oils, rubber compounding, and fuel oil applications.

Harmful Compounds Extraction

The FW Solvent Extraction Plant efficiently extracts harmful compounds such as:

Polycyclic Aromatic Hydrocarbons (PAHs)

Harmful compounds from waste oil.

Gums and Asphaltenes

Viscous impurities affecting performance.

Sulfur, Nitrogen & Oxygen Compounds

Chemical contaminants degrading quality.

⚠️ Impact of Impurities

These impurities, if left untreated, significantly degrade the performance and stability of base oils, leading to reduced efficiency and potential equipment damage.

Process Advantages

Superior Quality Output

- High yield of premium-grade base oil

- Low energy & solvent consumption

- Eco-friendly operation with minimal emissions

- Comprehensive automation with remote monitoring

Operational Excellence

- Modular design - easy to scale or upgrade

- Real-time data logging and system diagnostics

- Enhanced process accuracy and safety

- Operational efficiency optimization

Integrated Solutions for Oil Processing

Our end-to-end solutions ensure facilities are equipped to deliver premium-quality lubricants while maintaining environmental responsibility and operational efficiency. We offer complementary solutions to meet diverse processing needs:

Lube Oil Blending Plant

Precision blending systems for automotive and industrial lubricants.

Waste Oil Recycling Plant

Sustainable regeneration of used oils into high-quality base stocks.

Desulfurization Plant

Advanced sulfur removal systems to meet environmental compliance.

Industrial Applications

The FW system is designed for various industrial applications requiring efficient base oil processing and recovery, ideal for lubricant manufacturers, waste oil recyclers, and environmental service providers:

Used Engine Oils

Re-refining used engine oils for recovery.

Hydraulic & Gear Oils

Processing hydraulic oils and gear oils.

Industrial Lubricants

Recycling industrial lubricants.

Base Oil Production

Producing Group I and Group II base oils.

Technical Specifications

Recovery Rate

98% Group I+ Base Oil

Solvent Recovery

98%+ recovery rates

Feedstock

Waste Oil Specific

Automation

PLC/SCADA with Remote Monitoring

Scalability

Custom Requirements

Environmental

Market Standards Compliant

Our Advantages

- High yield of premium-grade base oil with 98% recovery rate

- Low energy & solvent consumption for cost efficiency

- Eco-friendly operation with minimal emissions

- Modular design - easy to scale or upgrade

- Comprehensive automation with remote monitoring

- Comprehensive technical support and maintenance

FW Solvent Extraction Plant

Advanced Base Oil Purification Technology

The FW Solvent Extraction Plant is designed to remove undesirable impurities from base oils, especially those derived from waste oil refining. This includes the efficient extraction of harmful compounds such as Polycyclic Aromatic Hydrocarbons (PAHs), gums, asphaltenes, sulfur, nitrogen, and oxygenates.

Fossil Wood Engineering Services has redesigned the conventional solvent extraction process with a continuous reverse solvent extraction column. This advanced technology enhances base oil quality by improving:

- Viscosity Index

- Oxidation Stability

- Carbon Residue

- Color and Clarity

Unmatched Solvent Efficiency

Our exclusive solvent extraction and recovery technology achieves over 98% yield of Group I+ base oil using as little as 1 kg of solvent, which reduces operational costs and environmental impact.

High-Value By-Products

Raffinate (Neutral Oil)

High-purity base stock suitable for blending into a wide range of lubricants.

Extract Fluid

Rich in aromatic content, ideal for use in process oils, rubber compounding, and fuel oil applications.

Key Features & Benefits

Designed for waste oil feedstock

High solvent recovery rates (98%+)

Continuous reverse extraction technology

Improved oil properties across the board

Modular & scalable for custom requirements

Low solvent consumption = High ROI

Integrated Solutions for Oil Processing

Explore complementary solutions to meet diverse processing needs:

Lube Oil Blending Plant

Precision blending systems for automotive and industrial lubricants.

Waste Oil Recycling Plant

Sustainable regeneration of used oils into high-quality base stocks.

Desulfurization Plant

Advanced sulfur removal systems to meet environmental compliance.

Our end-to-end solutions ensure your facility is equipped to deliver premium-quality lubricants while maintaining environmental responsibility and operational efficiency.

FW Base Oil Extraction Plant

A cutting-edge solution for efficient recovery and purification of high-quality base oils from used or waste lubricants, emphasizing its advanced solvent extraction technology, superior product yield, environmental compliance, and operational safety.

Core Systems & Features

Our plant includes the following integrated systems to ensure maximum efficiency and performance:

Heater & Heat Exchange System

- •High-efficiency thermal oil heaters and heat exchangers

- •Preheats feedstock for optimal process performance

- •Reduces energy consumption through heat recovery technology

Multistage Solvent Extraction System

- •High-efficiency thermal oil heaters and heat exchangers

- •Preheats feedstock for optimal process performance

- •Reduces energy consumption through heat recovery technology

Base Oil Desolvent System

- •Strips residual solvent from extracted base oil

- •Ensures high-purity end products with minimal solvent traces

- •Uses vacuum distillation or steam stripping methods

Solvent Recovery System

- •Recovers and recycles solvents used in the extraction process

- •Minimizes solvent loss and reduces operational costs

- •Environmentally friendly, with closed-loop circulation

Exhaust Purification System

- •Treats gases and vapors before atmospheric release

- •Equipped with scrubbers, filters, and activated carbon systems

- •Meets international environmental standards (e.g., EPA, EU norms)

PLC/SCADA Control System

- •Fully automated plant operations with centralized monitoring

- •Real-time data logging, alarms, and system diagnostics

- •Enhances process accuracy, safety, and operational efficiency

Applications

- •Re-refining used engine oils, hydraulic oils, gear oils, and industrial lubricants

- •Producing Group I and Group II base oils suitable for blending

- •Ideal for lubricant manufacturers, waste oil recyclers, and environmental service providers

Advantages of FW Technology

- High yield of premium-grade base oil

- Low energy & solvent consumption

- Eco-friendly operation with minimal emissions

- Modular design - easy to scale or upgrade

- Comprehensive automation with remote monitoring