Painting System

High productivity complete paint line, paint production plant, and paint making machine solutions

Painting System Technology

Complete turnkey solutions for high-productivity paint production lines, including paint manufacturing plants and advanced paint making machines for industrial applications.

Our painting systems are designed for maximum efficiency, quality control, and production capacity, serving various industries including automotive, construction, and industrial manufacturing.

- High Productivity Complete Paint Line

- Paint Production Plant

- Paint Making Machine

- Automated Control Systems

- Quality Assurance Systems

- Custom Formulation Capabilities

- Filling and Packaging Solutions

- Utilities and Infrastructure

Painting Plant Overview

Watch our comprehensive painting system in action, showcasing the complete production process from raw materials to finished product.

Paint and New Energy Processing Machine

Fossil Wood Engineering is one of the leading paint equipment manufacturers, focusing on complete sets of equipment design, manufacturing, and project solutions for paint & coatings manufacturing machines, new energy making machines, paint filling packing machines, and more. We always provide better products and services to our clients!

Paint Milling Machine Technology

A paint milling machine, also known as a paint grinding machine, is used for paint mixing and milling, inks, pigments, and other coatings to produce a uniform, fine particle size. The milling process is an essential step in the production of high-quality paint, ensuring consistent texture, color, and performance.

There are different types of paint milling machines, including ball mills, bead mills, and three-roll mills. These machines can be used for various paint formulations, including water-based, solvent-based, and high-solid content paints.

Paint milling machines can be used for different paint applications, such as decorative, industrial, and automotive paints. They are critical pieces of equipment in paint production, ensuring that the paint has the desired texture, color, and performance.

Architectural Coatings

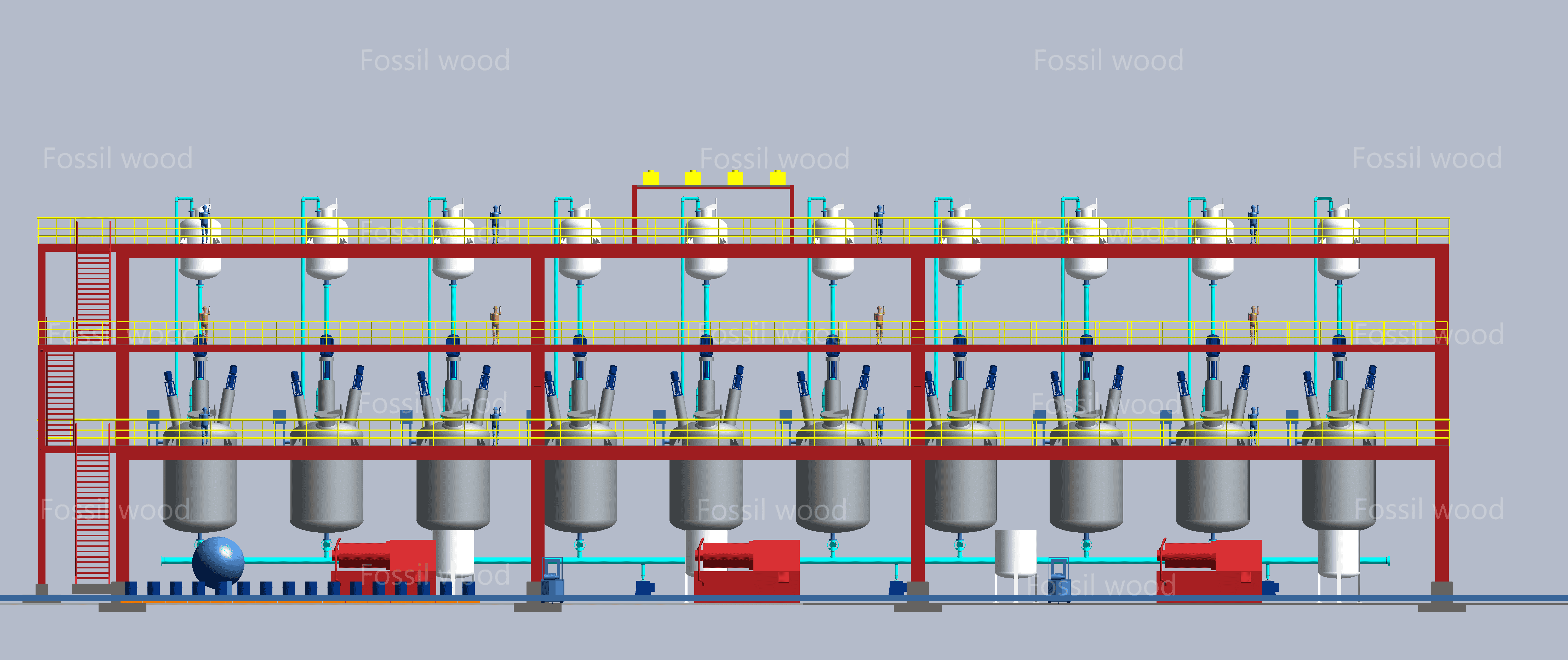

Complete production equipment for architectural paint formulations, featuring multi-level industrial setups with advanced mixing and processing capabilities.

Furniture Coatings

Specialized production lines for furniture paint formulations, featuring yellow cylindrical tanks and multi-tiered processing structures.

Waterproof Paint

Large-scale production facilities for waterproof paint formulations, featuring complex networks of tanks, pipes, and structural elements.

Polyester Paint

Complete polyester paint production line equipment, featuring multi-level industrial plants with advanced conveyor and mixing systems.

Paint Production Line

Fossil Wood Engineering provides complete turn-key solutions for the manufacturing of all types of paints, coatings, inks, and related products. Our systems include comprehensive paint plant lines, designed for efficient, high-quality, and automated production. As a professional paint production line company, Fossil Wood Engineering Machinery has own paint production line and specialized in automatic paint filling machine for sale.

Enhanced Safety

Automated processes significantly reduce manual labor, minimizing accidents and injuries while maintaining strict safety protocols throughout the production line.

Improved Productivity

Dramatically increases output capacity, enabling manufacturers to meet growing customer demand while boosting overall profitability and market competitiveness.

Cost Savings

Reduces waste through precise control, improves operational efficiency, and significantly lowers operating costs while maintaining high-quality output.

Increased Efficiency

Streamlines the entire manufacturing process, reducing time and effort while producing consistently high-quality paint with minimal resource waste.

Consistent Quality

Maintains uniform paint quality and texture through standardized processes, significantly reducing defects and ensuring customer satisfaction.

Reduced Waste

Minimizes environmental impact through precise control of raw materials, reducing waste generation while maintaining production efficiency.

Overall Impact

Our paint production lines deliver increased efficiency, consistent quality, reduced waste, enhanced safety, improved productivity, and significant cost savings. These comprehensive benefits enable manufacturers to meet growing demand, increase profitability, and maintain a competitive edge in the market.

What Equipment is Used in Producing Paint?

There are several types of equipment used in producing paint. Here are some examples of the specialized machinery that ensures high-quality, consistent paint production.

Mixers and Blenders

Machines used to blend raw materials like pigments, resins, and solvents into a homogeneous mixture.

Mills

Used to grind and disperse pigments and other solid particles into the paint for uniform consistency.

Filling Machines

These machines are used to fill paint into various containers such as cans, bottles, or drums, and to seal them with lids or caps.

Dispensing Machines

Used for accurately measuring and dispensing different raw materials in paint production. They can be programmed to dispense precise amounts for consistency.

Filters

Used to remove impurities or particles from the paint before it is filled into containers, ensuring a contaminant-free product with uniform texture.

Quality Control Equipment

Various testing equipment like viscosity meters, colorimeters, and gloss meters, which are used to ensure the paint meets required quality standards.

Production Setup Overview

Multi-Level Industrial Platform

Ground Level Operations

Quality Assurance

Overall, paint production requires a range of specialized equipment to ensure that the paint is of high quality, consistent in texture and color, and meets the required safety standards.

Why Choose Fossil Wood Engineering

Choosing the right partner for your paint production line is a critical decision that impacts your quality, efficiency, and long-term profitability. Here's why Fossil Wood Engineering is the ideal choice for your business.

Proven Excellence and Reputation

With years of expertise in paint manufacturing equipment, Fossil Wood Engineering has established a strong reputation for reliability and performance. Our satisfied clients and successful project portfolio speak to our consistent delivery of top-tier solutions.

Custom Solutions and Flexibility

We understand that every client's needs are unique. Our team excels in creating tailored paint production line solutions designed to meet your specific requirements, allowing you to scale and adapt as your business grows.

Quality and Safety Assurance

All our equipment meets international quality and safety standards, ensuring your production line runs safely, efficiently, and in compliance with regulatory guidelines.

Innovation Leadership

At Fossil Wood Engineering, we invest continuously in the latest technologies to offer you the most advanced and efficient solutions. Our innovative approach ensures your production line remains competitive and future-ready.

Water-Based and Solvent-Based Paint Production Equipment/Line

Complete production solutions for both water-based and solvent-based paint manufacturing, featuring advanced equipment and comprehensive specifications for optimal performance.

Industrial Production Setup

Multi-Tiered Platform

Ground Level Operations

Control and Support

Equipment Types

High Speed Paint Mixer

Large stainless steel mixing tank with motor system for efficient paint blending and dispersion.

Water-Based Wood Emulsion Production Line

Complete production line featuring multiple white cylindrical tanks and associated piping for emulsion manufacturing.

Stainless Steel Jacketed Reactor

Chemical industry reactors with jacketed design for temperature control and efficient processing.

Product Information

Water-Based Paint Production

Environmentally friendly paint production using water as the primary solvent, featuring specialized equipment for emulsion and water-based formulations.

Solvent-Based Paint Production

Traditional paint production using organic solvents, featuring advanced equipment for high-performance coatings and industrial applications.

Comprehensive Paint Production System

Advanced production line featuring complete automation, versatile processing capabilities, and integrated systems for both water-based and solvent-based paint manufacturing.

Main Features

Independently completes dispersing, grinding, vacuum suction, semi-auto filling, etc.

Slurry mixing and color mixing are executed in one tank.

Capable of producing both water-based and solvent-based paint.

Capacity tanks range from 500-1000L.

System Structure

Production Line Equipment

| System | Equipment Items | Remarks |

|---|---|---|

| Control System | Electrical control system | Subassembly |

| Materials Feeding System | Powder feeding tank | 304 Stainless steel, inside and outside mirror polished |

| Liquid feeding tank | 304 Stainless steel, inside and outside mirror polished | |

| Latex feeding tank | 304 Stainless steel, inside and outside mirror polished | |

| Vacuum buffer tank | 304 Stainless steel, inside and outside mirror polished | |

| Additive feeding tank | 304 Stainless steel, inside and outside mirror polished | |

| Vacuum pump | Water vane type | |

| Dispersing vessel | 304 Stainless steel with top and down dished end, inside and outside mirror polished | |

| Grinding System for Paste Making | Horizontal sand mill | Macromolecule grinding disc |

| Basket mill | Inverter control (0-1440), with sealing device | |

| Tinting System | Multifunction mixing vessel | With top and down dished end, inside and outside mirror polished, sealing device |

| High speed disperser | Inverter control (0-1440 rpm) with sealing device | |

| Discharging and Filtration System | Pneumatic diaphragm pump | DN40 |

| Bag type filter | 304 Stainless steel | |

| Operation Platform | Operation platform | Size:5x3x1.8M, stainless steel |

| Pipeline System | Pipeline accessories | Include all valves, quick joints, stainless steel pipeline and cables |

| Filling System | Filling System | Semi-auto filling machine |

Related Equipment

Feeding Tank

Large cylindrical stainless steel tanks connected by piping

Horizontal Sand Mill

Compact teal-colored industrial machine with control panel

High-Speed Disperser

Tall white industrial mixer with motor and mixing blade

Storage Tank

Large grey cylindrical tank with wheels for mobility

Filling Machine

Semi-automatic machine with conveyor belt and nozzle

Bag Type Filter

Blue industrial filtration unit with pipes and pressure gauge

Industrial Machinery & Services

Industrial Equipment

Feeding Tank

Multiple cylindrical stainless steel tanks connected by piping

Horizontal Sand Mill

Compact blue and green industrial machine for fine milling

High-Speed Disperser

Grey industrial unit with vertical shaft and disc mixing head

Storage Tank

Large grey cylindrical tank with wheels for mobility

Filling Machine

Stainless steel machine with multiple nozzles and conveyor belt

Bag Type Filter

Blue industrial system with pump, hoses, and filter housing

Mixing Tank

Grey cylindrical tank with motor and agitator mounted on top

Global Reach

Worldwide service and support capabilities

After-Sales Service

Warranty

One year warranty from date of delivery for spare parts, with free replacements for parts broken within warranty not caused by improper operation.

Support

Provision of professional after-sales service engineers for overseas installation and debugging.

Pre-Sales Services

Packaging & Shipping

Why Choose Fossil Wood?

8+ Years Experience

More than 17 years of experience in the Cosmetic and Chemical industry.

Quality Assurance

80% of materials and components purchased from reputable brands like 3M, ABB, Siemens, Panasonic, and Schneider.

Good Reputation

Excellent reputation in the industry with proven track record.

Professional Team

Possession of a professional after-sales service engineering team.

Large Scale

Large scale operations with strong manufacturing capabilities.

Global Reach

Worldwide service and support with international shipping capabilities.

High Productivity Complete Paint Line

Our high productivity complete paint line systems are engineered for maximum efficiency and output, designed to meet the demanding requirements of modern industrial paint production.

These systems integrate advanced automation, precise control mechanisms, and state-of-the-art equipment to ensure consistent quality and high production capacity.

- Automated batch processing and control

- Precise ingredient dosing and mixing

- Advanced quality monitoring systems

- High-capacity production capabilities

- Flexible formulation management

- Integrated packaging and filling solutions

Paint Production Plant

Complete paint production plants designed for industrial-scale manufacturing, incorporating the latest technology and best practices in paint formulation and production.

Our plants feature modular design for easy expansion, comprehensive quality control systems, and energy-efficient operations to maximize productivity while minimizing costs.

- Raw material storage and handling systems

- Automated mixing and blending units

- Quality control laboratories

- Filling and packaging systems

- Environmental control systems

- Safety and monitoring equipment

Paint Making Machine

Advanced paint making machines engineered for precision, efficiency, and reliability in paint production processes.

These machines incorporate cutting-edge technology for optimal mixing, grinding, and processing of paint formulations, ensuring consistent quality and performance.

- High-speed dispersers and mixers

- Precision grinding and milling systems

- Automated temperature and pressure controls

- Advanced monitoring and control systems

- Easy maintenance and cleaning procedures

- Scalable capacity options

System Capabilities

Comprehensive technical specifications and capabilities of our painting system solutions.

Production Capacity

Quality Control

System Components

Comprehensive range of equipment and components for complete painting system solutions.

High Productivity

Complete paint line with high production capacity.

Paint Production

Full paint manufacturing and processing systems.

Paint Making Machine

Advanced paint production equipment.

Automation

Automated control and monitoring systems.

Quality Control

Comprehensive testing and quality assurance.

Custom Formulations

Tailored paint formulations for specific needs.

Filling Systems

Automated packaging and filling solutions.

Utilities

Essential support systems and infrastructure.

Lab Instruments

Quality control and testing equipment.

Structural Work

Robust plant infrastructure and support.

Applications & Industries

Industrial Applications

- • Automotive paint manufacturing

- • Industrial coating production

- • Architectural paint systems

- • Marine and protective coatings

- • Powder coating production

- • Specialty paint formulations

Key Benefits

- • High production efficiency

- • Consistent quality control

- • Reduced waste and costs

- • Flexible formulation options

- • Automated operation

- • Scalable production capacity