Brake Fluid Manufacturing Plants

Complete turnkey solutions for state-of-the-art brake fluid manufacturing with 100% hygroscopic control and 99% moisture-free output

CAPACITY: 1,000 TO 10,000 LTRS/DAY

Brake Fluid Plant Solutions

Fossil Wood Engineering provides fully integrated brake fluid plant solutions on a turnkey basis, encompassing front-end and back-end design, as well as complete EPC (Engineering, Procurement, and Construction) services.

Our plants are engineered to be 100% hygroscopic, ensuring optimal quality in brake fluid production. The brake fluid manufactured in our systems is over 99% moisture-free, guaranteeing superior performance.

- Complete Turnkey Solutions

- 100% Hygroscopic Control

- 99% Moisture-Free Output

- Advanced Processing Units

- Precision Piping Systems

- Integrated Packaging Facilities

- Quality Control Systems

- Safety & Compliance Standards

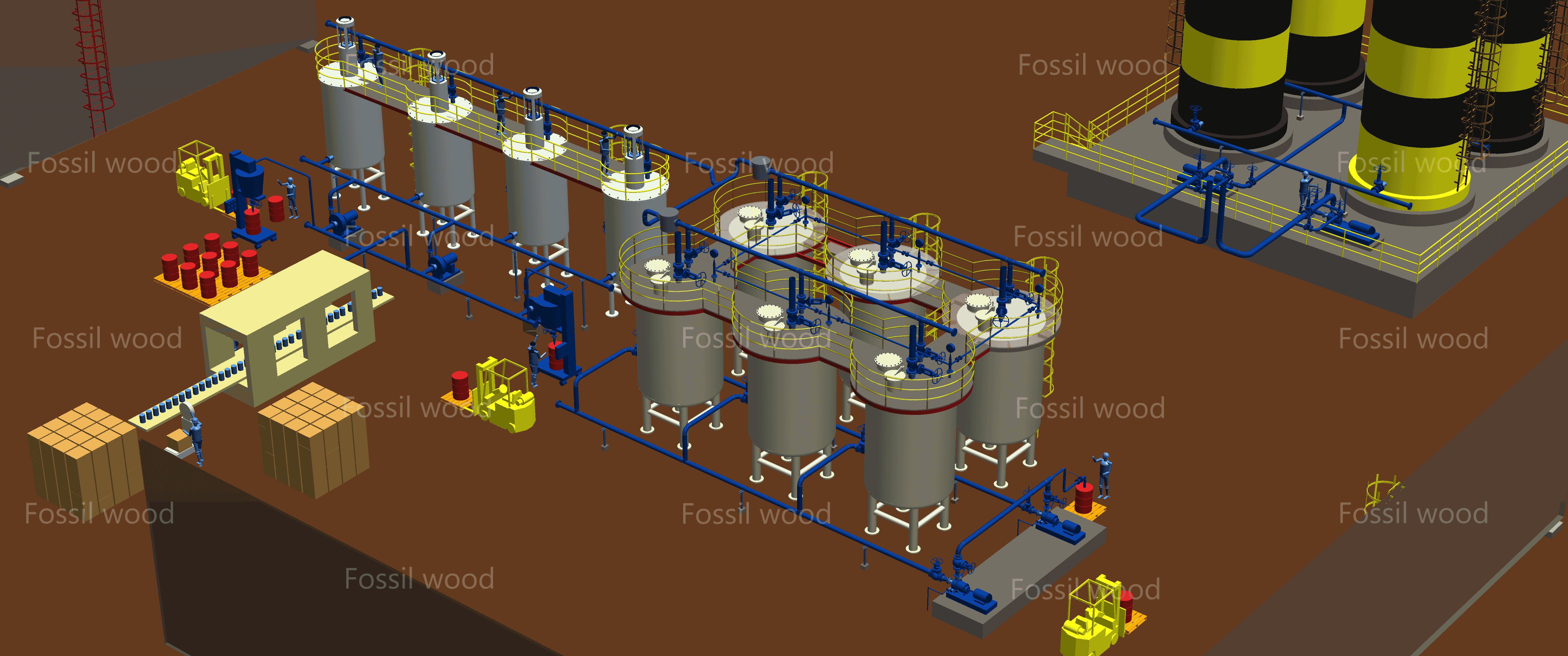

Brake Fluid Plant Overview

Watch our comprehensive brake fluid manufacturing system in action, showcasing the complete production process with 100% hygroscopic control and 99% moisture-free output.

State-of-the-Art Plant Design

Our brake fluid manufacturing plants feature advanced processing units, precision piping systems, and integrated packaging facilities designed for maximum efficiency and quality control.

Processing Units

Large cylindrical tanks with integrated mixing systems, agitators, and temperature control for precise brake fluid formulation and quality assurance.

Advanced Piping Network

Comprehensive blue and red piping system connecting all processing units, ensuring efficient material flow and precise control over the manufacturing process.

Quality Control Systems

Integrated monitoring and control systems with yellow safety railings and access platforms for safe operation and maintenance procedures.

Storage & Packaging

Dedicated storage tanks and packaging facility with conveyor systems for efficient product handling and distribution, ensuring 99% moisture-free output.

Safety & Compliance

Built to meet global industry standards with comprehensive safety systems, emergency protocols, and regulatory compliance for brake fluid production.

Brake Fluid Properties & Performance

Critical Component in Braking Systems

Brake fluid plays a vital role in the efficiency and safety of braking systems. As a specialized hydraulic fluid, it is essential in motorcycles, cars, and light trucks. Its primary function is to transmit force from the brake pedal to the braking mechanism at the wheels through hydraulic lines.

Because fluids are virtually incompressible, brake fluid effectively delivers pressure where it's needed most—ensuring smooth and responsive braking.

Performance Requirements

Braking systems generate substantial heat during operation, requiring brake fluids with a high boiling point to remain effective under intense conditions. These fluids must also resist freezing under typical ambient temperatures.

Due to these performance requirements, most water-based solutions are unsuitable.

DOT Classification System

The quality and safety of brake fluids are primarily defined by their boiling point. Brake fluids are categorized under the DOT (Department of Transportation) classification system:

DOT 2

Primarily castor oil-based fluids with basic performance characteristics.

DOT 3, 4 & 5.1

Composed of mineral oils and glycol esters, offering enhanced performance and safety.

DOT 5

Silicone-based fluids used exclusively by the US Army since 1982.

Brake Fluid Properties & Characteristics

DOT 3 & 4 Properties

Among these, DOT 3 is the most commonly used in vehicles across the United States. Both DOT 3 and DOT 4 are polyethylene glycol-based fluids and are hygroscopic, meaning they absorb moisture from the atmosphere.

This moisture absorption reduces the boiling point and overall effectiveness of the fluid over time.

While this may not be critical for standard passenger vehicles, it poses a significant concern for high-performance race cars and motorcycles.

Performance Characteristics

Glycol-based brake fluids, like DOT 3 and DOT 4, offer low compressibility—even when heated—resulting in a firmer brake pedal feel.

These fluids can degrade over time due to moisture absorption, impacting hydraulic efficiency. Regular fluid replacement—ideally every two years—helps maintain braking performance.

Brake fluid components, especially polyethylene glycol, can be corrosive to paint, chrome, and other finishes, so careful handling is essential during maintenance.

Brake Fluid Contamination: What You Need to Know

Contamination Risks

Brake fluid, like other vehicle fluids, deteriorates over time and requires replacement, even if not specified in the vehicle's manual. It becomes vulnerable to contamination from worn-out hoses and lines, and moisture introduction when opening the master cylinder.

Improper bleeding can trap air, compromising performance. High temperatures during braking can degrade the fluid in calipers or wheel cylinders. These factors reduce braking efficiency and safety, making timely brake fluid replacement critical.

Contamination Sources

Over time, brake fluid becomes susceptible to contamination through:

- •Aging hoses and deteriorated lines

- •Moisture absorption during master cylinder inspections

- •Improper bleeding leading to air retention

- •Heat degradation within calipers and cylinders

These factors reduce brake efficiency and safety, and routine replacement helps maintain optimal performance and protect braking components.

Automotive Lubricants Market Overview

Global Market Growth

The global automotive industry is poised for significant growth, with the lubricants sector maintaining its position as a key contributor. With technological advancements and increasing vehicle demand, the need for high-performance automotive lubricants has reached unprecedented levels.

India Market Leadership

India ranks as the sixth-largest lubricant market in the world, hosting major multinational corporations such as Shell, Mobil, Gulf Oil, and Caltex. Many of these companies have established or renewed partnerships with public sector enterprises, leveraging strong distribution networks and infrastructure.

India Production Evolution

Historically, India produced primarily basic blends using low- to medium-level technology. However, the landscape has evolved, and modern high-performance lubricants are now widely available, tailored to diverse automotive needs—ranging from affordability to high-end racing specifications and extended fluid life.

Challenges and Expansion

Despite growth, the industry faces challenges due to rising petroleum costs. Nonetheless, product variety continues to expand, driven by increasingly specialized customer demands.

Key Features of Our Brake Fluid Plant

Comprehensive solutions designed for maximum efficiency, quality, and reliability in brake fluid manufacturing.

Precision Engineering

Designed for consistent, high-quality blending of brake fluids

Turnkey Delivery

Full-spectrum solutions from design to commissioning

Advanced Machinery

Cutting-edge technology for superior production efficiency

Customizable Systems

Adaptable to various formulations and market requirements

Regulatory Compliance

Built to meet global industry standards

Streamlined Workflow

Optimized production flow from raw material to final packaging

Global Recognition

Trusted by clients worldwide for dependable performance

Technical Support

Comprehensive assistance to keep operations running smoothly

Innovation-Driven

Keeping your plant ahead with the latest technologies

Cost-Efficient

Designed to maximize output while minimizing resource use