Dry Mix Mortars & Wall Putty Plants

Made from environment-friendly materials with advanced vertical and horizontal plant configurations.

Dry Mix Mortars

Comprehensive dry mix mortar and wall putty manufacturing plants designed for high-efficiency production using environment-friendly materials.

Capacity ranging from 5 MT/HR to 100 MT/HR.

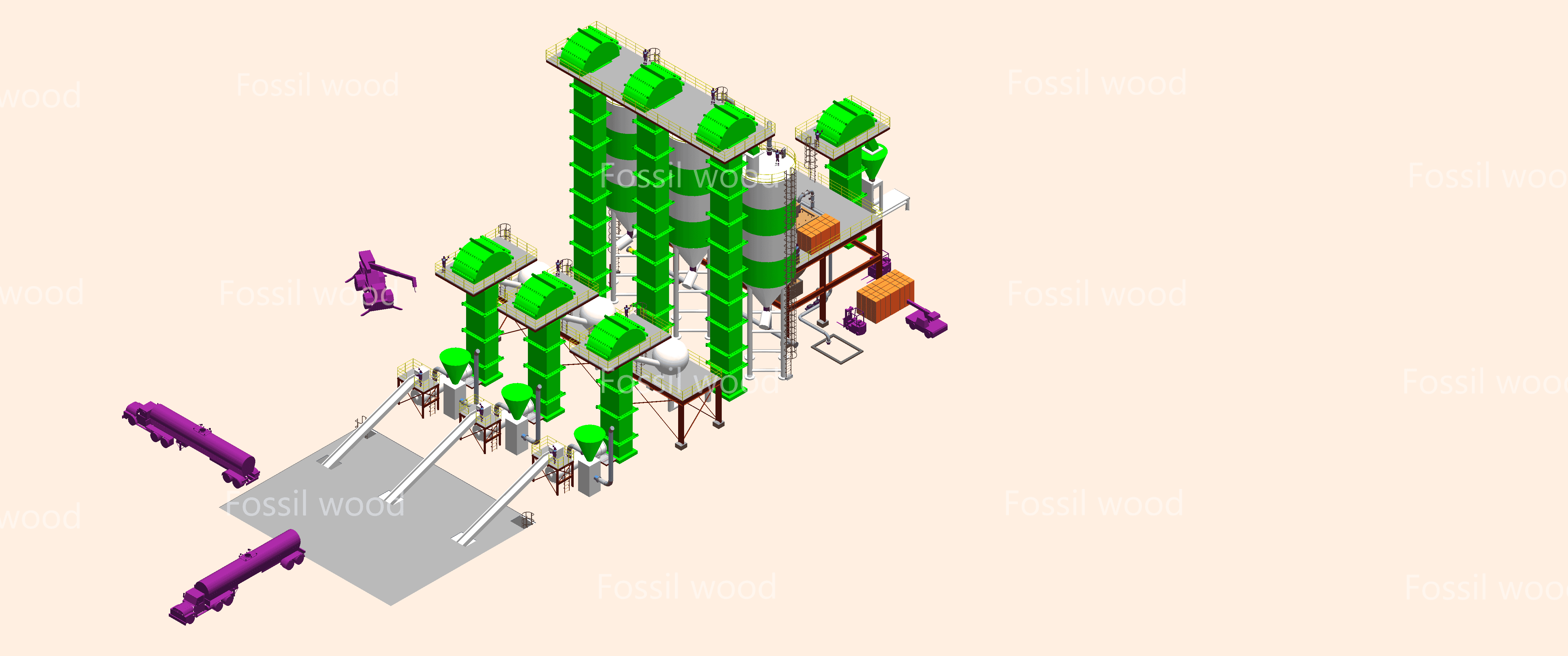

Horizontal Plant

Ground-level layout with 5-20 MT/HR capacity

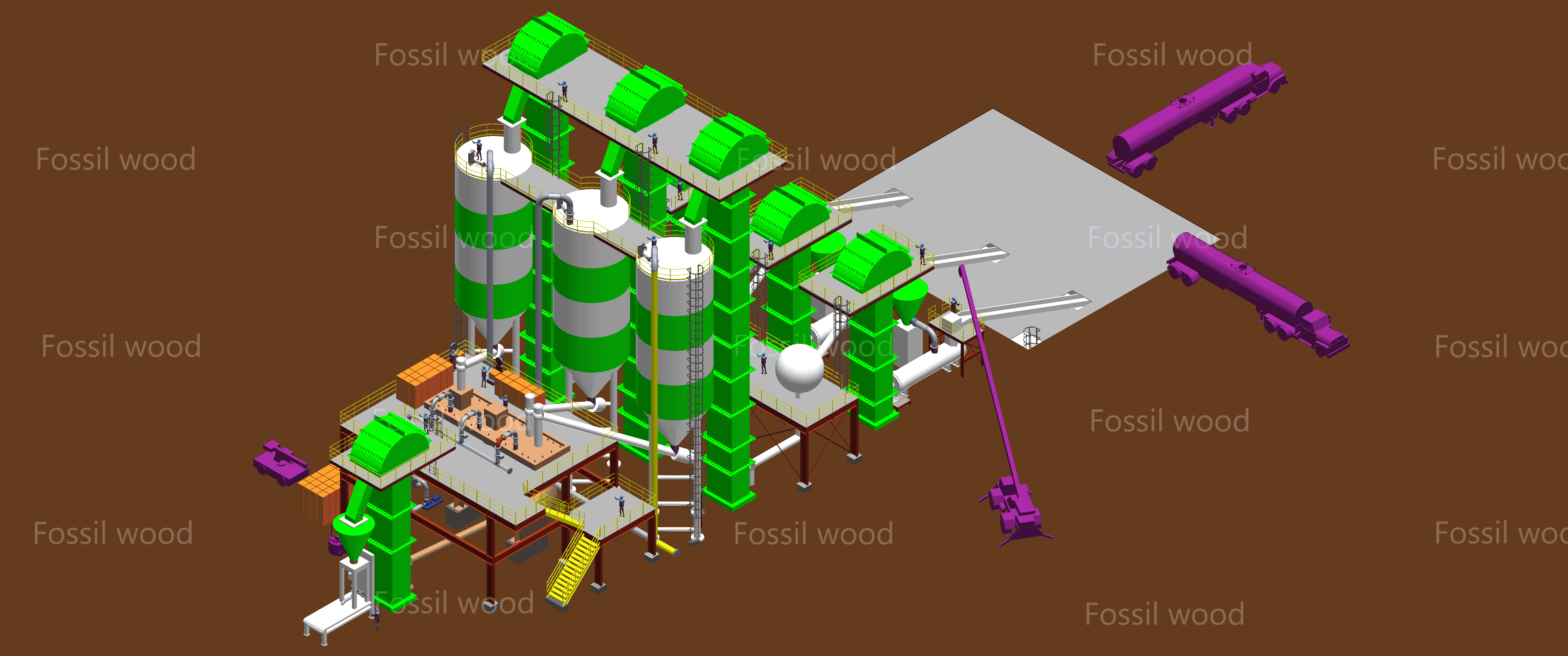

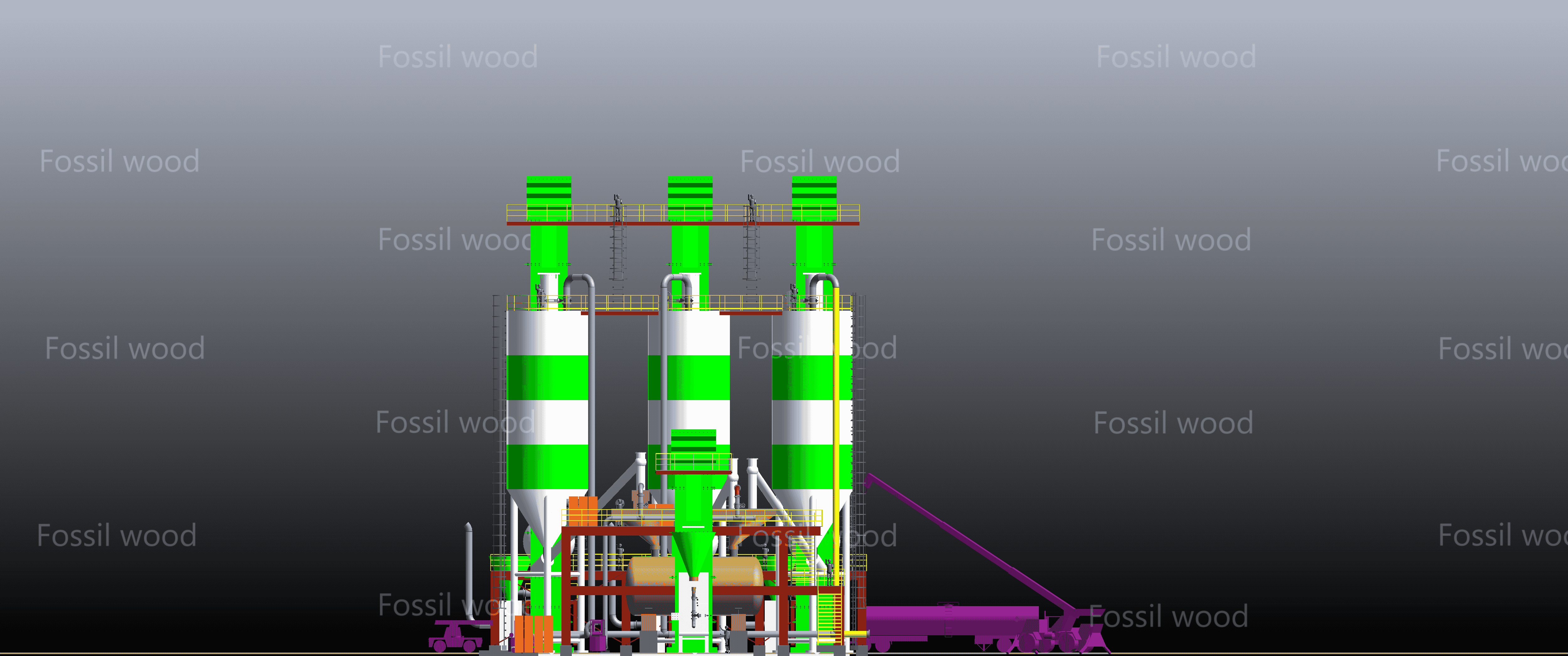

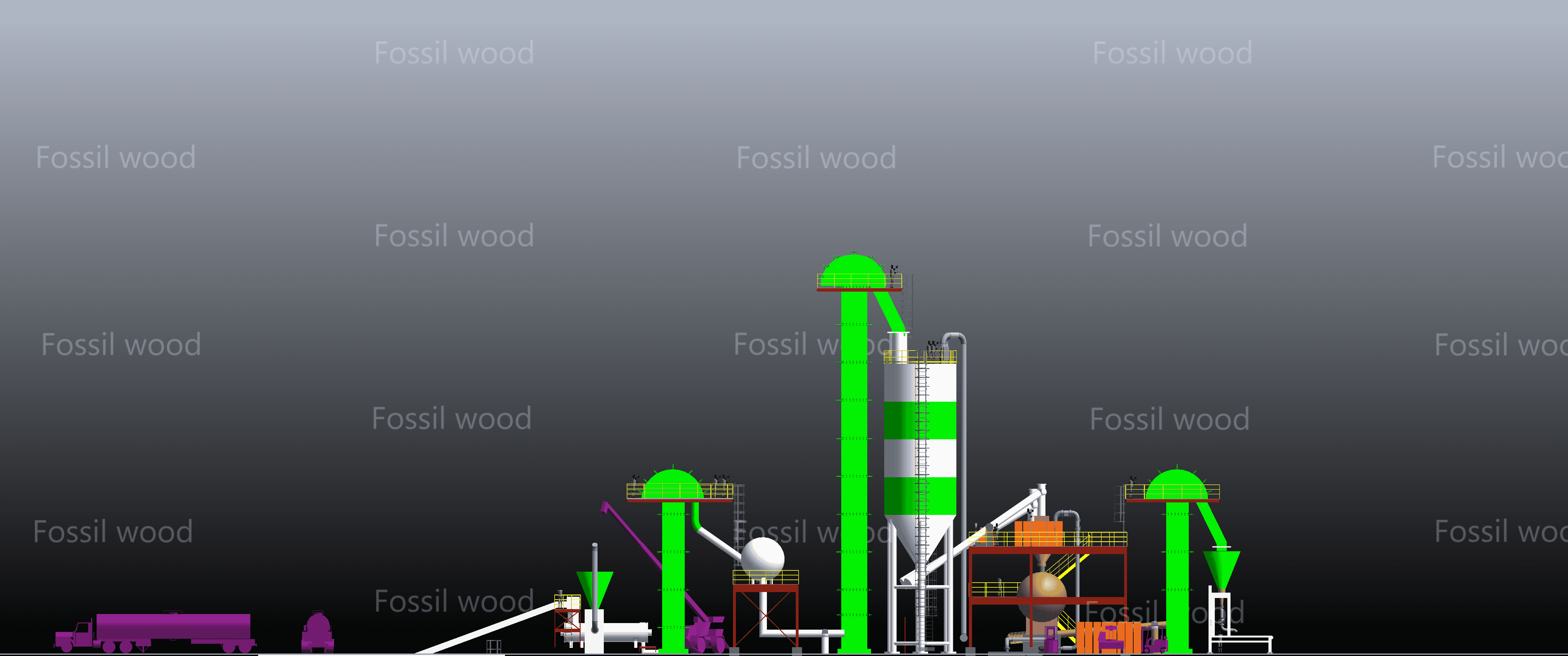

Vertical Plant

Tower design with 20-100 MT/HR capacity

Batch Plants

Semi-automatic plants for 10-50 MT daily capacity

Admix Plant

Super plasticizers and additives manufacturing

Sand Drying

Moisture control for quality consistency

Packing

Automated packaging solutions

Lab Equipment

Quality control and testing facilities

Dry Mix Mortar Plant Overview

Watch our comprehensive dry mix mortar and wall putty manufacturing system in action, showcasing the complete production process from raw materials to finished products.

Sand Drying Plants

Made from environment friendly materials

Wet unscreened sand is manually charged into a feed hopper, transferred by a bucket elevator to a storage hopper with a rotary feed valve, then passed through a dryer where it's heated by a burner, rotated, and cascaded for heat transfer. After drying, it's charged onto a belt conveyor, then to a vibrating screen for fractionation, and finally collected from the floor level for transfer to sand silos via bucket elevators. A sand cooler is mentioned as an optional component.

Advantages

Mobile and flexible plan

Portable design for easy relocation and deployment

Plug and play system

Quick installation and immediate operation capability

Ideal for new ventures/startups

Perfect solution for emerging businesses and startups

The plant design is a comprehensive, single-source solution covering civil, mechanical, electrical, and chemical processes, aiming to minimize client scope of work. It emphasizes leveraging manufacturing experience for know-how and training.

A state-of-the-art laboratory meets and exceeds international specifications, guaranteeing high quality. The plant design adheres to global standards and incorporates advanced safety features for secure and efficient operation.

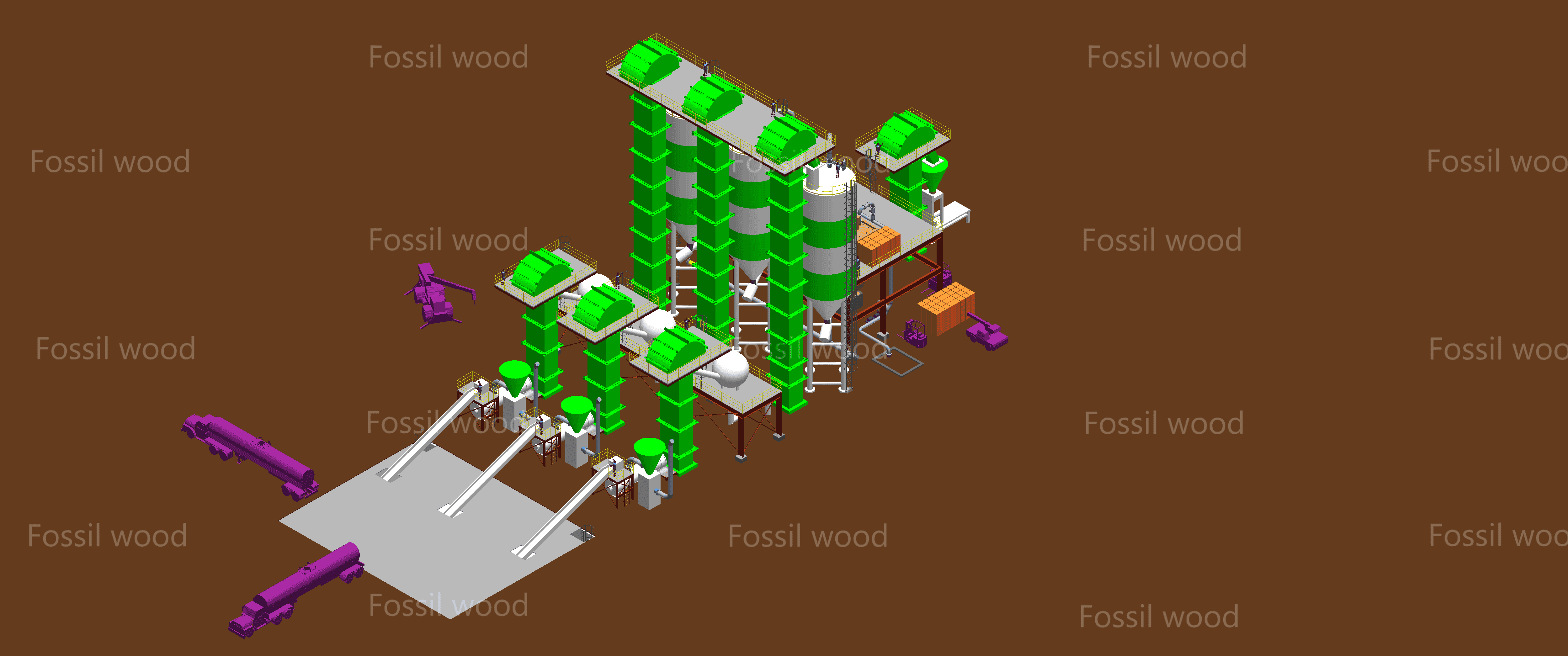

Vertical Plants

Vertical plants feature a gravity-leveraging design with capacities ranging from 20-100 MT/HR. The efficient material flow operates from ground level to silos, integrating blowers and conveyors. A screening process is positioned atop the structure, with storage for various raw materials including cements, sands, minerals, fly ash, silica fume, fine dust, and additives.

Transfer methods include screw conveyors, loss-in-weight feeders, vibratory, and pneumatic feeders. The design reduces conveying distance and power consumption while ensuring precise weighing, batching, and charging into mixers (plough or twin-shaft) with mixing duration of 1-5 minutes. Final packaging is into paper or HDPE bags (open-mouth or valve-type) or bulk bags/silos/bulkers.

Plant Sections

Advantages

Horizontal Plants

Horizontal plants are prevalent across industries with capacities ranging from 5-20 MT/HR. The optimized layout features ground-level silos with efficient material conveyance via truck-mounted or on-site blowers. The system typically includes 2-10 silos for storing diverse materials including cement, sand, minerals, fly ash, silica fume, fine dust, polymers, cellulose, starch ethers, and air entrain agents.

The process involves meticulous weighing, batching, and charging into high-turbulence mixers (plough or twin-shaft) with mixing duration of 1-5 minutes. Final packaging is into paper or HDPE bags (open-mouth and valve-type). The system features state-of-the-art plant automation with PLC-controlled recipe management software for precise control and quality assurance.

Key Features

- Ground-level silo configuration

- PLC-controlled automation

- High-turbulence mixing technology

- Recipe management software

Batch Plants

Our semi-automatic batch plants are designed for daily capacities of 10 to 50 metric tons (MT) over 8 hours of operation. These plants are ideal for smaller market ventures, offering efficiency, dust-free environment, and organized production processes.

Raw materials are transferred to the mixer via a comprehensive conveyor system including bucket, screw, or belt conveyors. The plant operates in semi-automatic mode, requiring 6-8 individuals for optimal operation. A key feature is the floor-level entry of raw materials into a weigh batch hopper, with automation and PLC-controlled recipe management software orchestrating the transfer process.

Advantages

Key Features

- Semi-automatic operation (6-8 personnel)

- Floor-level raw material entry

- PLC-controlled recipe management

- Dust-free environment

Admix Plant

Fossil Wood Admix Plants are designed to manufacture various super plasticizers, retarders, and accelerators for ready mix concrete and mortars. These plants are simple, cost-effective, and prioritize client interests by using locally sourced raw materials.

The manufacturing process involves precise steps: weighing, mixing, and filling. During production, water and liquid additives are pumped into the blender at a controlled rate, while powder additives are manually or automatically dosed. A mixing period of 50-60 minutes is followed by stringent quality checks (laboratory and field tests) before transfer to storage or filling.

We Offer Formulations for the Below Products

Process Features

- Controlled blending environment

- 50-60 minute mixing period

- Laboratory and field quality tests

- Comprehensive formulations meeting high standards

Technical Specifications

Vertical Plants

- Capacity: 20-100 MT/HR

- Design: Gravity-leveraging tower structure

- Material Flow: Ground level to silos with integrated conveyors

- Mixing: Plough or twin-shaft mixers (1-5 minutes)

- Packaging: Paper/HDPE bags, bulk bags, silos

Batch Plants

- Capacity: 10-50 MT daily (8 hours)

- Operation: Semi-automatic (6-8 personnel)

- Conveyors: Bucket, screw, or belt systems

- Entry: Floor-level raw material entry

- Control: PLC-controlled recipe management

Horizontal Plants

- Capacity: 5-20 MT/HR

- Layout: Ground-level silos with optimized spacing

- Silos: 2-10 silos for diverse material storage

- Automation: PLC-controlled recipe management

- Materials: Cement, sand, minerals, polymers, additives

Admix Plants

- Products: Super plasticizers, retarders, accelerators

- Process: Weighing, mixing, filling

- Mixing Time: 50-60 minutes

- Quality: Laboratory and field tests

- Standards: ASTM C494, EN L934, IS9103

Made from Environment-Friendly Materials

Sustainable Materials

Using eco-friendly raw materials and processes

Energy Efficient

Optimized designs reduce power consumption

Clean Production

Advanced dust collection and waste management