Waste Oil to Base Oil Plant

Revolutionary FW Series technology for eco-friendly re-refining of used lubricating oils into high-quality API Group I base oils.

Revolutionizing Waste Oil Re-refining

Revolutionizing Waste Oil Re-refining

The FW Series is an innovative process technology developed to re-refine used lubricating oils into high-quality API Group I base oils. This system offers an eco-friendly solution for oil recovery, transforming hazardous waste into a valuable resource while maintaining high performance standards.

Clean Separation, Maximum Efficiency

With a focus on sustainability and efficiency, the FW process separates water, fuel oil, additives, and sludge from used oils to recover clean base oil. This advanced method not only minimizes environmental pollution but also reduces dependency on crude oil-derived virgin base stocks.

World-Class Distillation Technology

Using Wiped Film Evaporation (WFE) under vacuum conditions, the FW Series achieves exceptional results in oil purification. Recognized as the most reliable commercial approach for re-refining, WFE ensures consistent output quality that meets stringent API Group I specifications.

Key Features:

Processes Multiple Oil Types:

Cutting-Edge Re-refining Solutions

Cutting-Edge Re-refining Solutions for Used Lubricating Oils

Our advanced re-refining technologies convert used lubricating oils into near-virgin quality base oils with viscosity grades ranging from SN80 to SN500. The solutions incorporate a combination of cutting-edge processes including Fully Continuous Distillation, Wiped Film Evaporation (WFE), and Short Path Distillation.

Our Solvent Extraction Plant eliminates the need for traditional clay-based systems, enabling clients to produce base oils that meet or exceed API Group I+ Specifications.

Efficient and Profitable Waste Oil Refining

The FW Waste Oil to Base Oil Plant is designed to process a wide variety of used oils including Motor Oil, Hydraulic Oil, Crankcase Oil, Gearbox Oil, Transmission Oil, and Slop Oil. This advanced refinery system offers an environmentally sound solution to waste oil management while helping reduce operational costs, delivering both sustainability and profitability.

Expanded Solutions for Greater Sustainability

Our broader commitment to the circular economy includes additional innovative systems such as the Waste Oil to Diesel Plant and the Lube Oil Refining Plant. These complementary technologies enhance the value of waste oil streams, offering comprehensive solutions aligned with operational efficiency and green energy objectives.

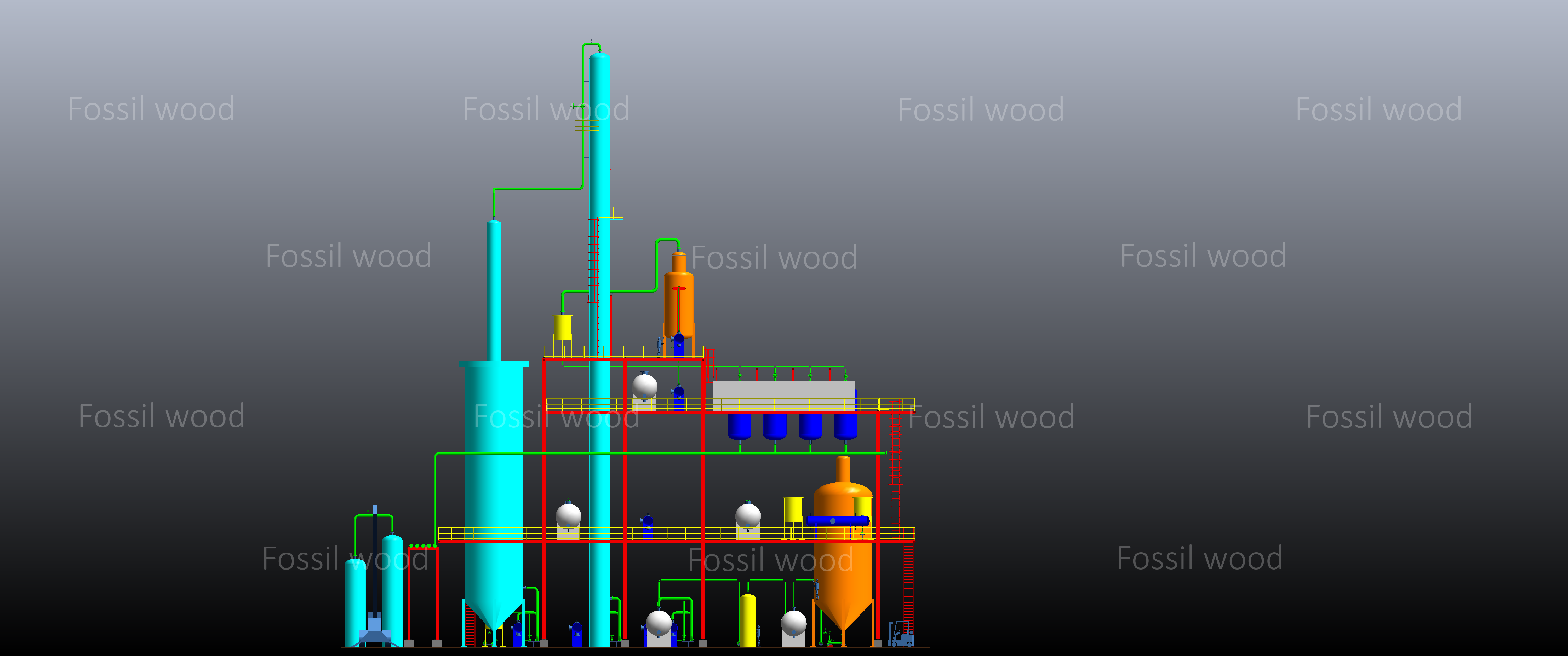

FW Waste Oil to Base Oil Plant Systems

The FW Waste Oil to Base Oil Plant consists of the following integrated systems, each designed to work in harmony to deliver maximum efficiency and quality output.

1. Dehydration and Sedimentation System

Removes moisture and suspended solids from the used oil, ensuring optimal feedstock quality for downstream processing.

2. LGO (Light Gas Oil) Stripping System

Extracts volatile light hydrocarbons from the feedstock, separating valuable components for further processing.

3. Fractionating and Reflux System

Separates oil components into distinct fractions for further processing, ensuring precise control over product quality.

4. Thin Film Evaporation System

Provides efficient thermal separation under vacuum conditions, maximizing recovery while minimizing thermal degradation.

5. Short Path Distillation System

Refines base oils with high purity and minimal thermal degradation, ensuring superior product quality.

6. Heaters and Heat Exchangers

Optimize thermal efficiency and energy usage throughout the process, reducing operational costs and environmental impact.

7. Base Oil Polishing System

Enhances the final quality and clarity of the re-refined base oil, ensuring it meets or exceeds industry specifications.

8. PLC/SCADA Control System

Delivers automated, centralized control and real-time monitoring for reliable plant operation and optimal performance.

Complete Process Flow

Collection & Pre-treatment

Used lubricating oils are collected and undergo initial pre-treatment to remove large contaminants and water.

WFE Distillation

Advanced Wiped Film Evaporation separates base oil from additives, sludge, and other contaminants under vacuum.

Quality Assurance

Final product undergoes rigorous testing to ensure it meets API Group I specifications and quality standards.

Environmental Benefits

Our waste oil re-refining technology represents a significant step forward in environmental protection and resource conservation. By transforming hazardous waste into valuable base oil, we contribute to a more sustainable future.

Waste Reduction

- Eliminates hazardous waste disposal

- Reduces landfill burden

- Prevents soil and water contamination

Resource Conservation

- Reduces crude oil consumption

- Conserves natural resources

- Promotes circular economy

Advanced Technology Features

Our FW series incorporates cutting-edge technology to ensure maximum efficiency, quality, and environmental compliance in waste oil re-refining.

Key Benefits

Our waste oil to base oil plant delivers comprehensive benefits across environmental, economic, and operational dimensions.

Technical Specifications

Process Specifications

- Technology: FW Series with WFE

- Distillation Methods: WFE + Short Path Distillation

- Operating Conditions: Vacuum conditions

- Output Quality: API Group I+ Base Oil

- Viscosity Grades: SN80 to SN500

- Process Efficiency: Maximum recovery rate

- Control System: PLC/SCADA automation

Quality Standards

- API Standards: Group I Base Oil specifications

- Environmental: Eco-friendly compliance

- Performance: High-quality output

- Consistency: Reliable production

- Safety: Hazardous waste handling

Technical Specifications & FAQs

1. WHAT ARE COMMONLY USED HEATING METHODS IN WASTE OIL REFINERIES?

There are three major heating methods: Electrical Heating, Boiler, and Furnace.

Electrical Heater

Often used in small-scale refineries. Advantages include a wide range of heating temperatures and economic solution for small scale.

Hot Oil Boiler

Can be used in medium to large-scale refineries. Heating by boiler in heat exchangers is common in the petrochemical industry. It is safe, efficient, and controllable. Most hot oil boilers have a temperature limit below 380-350°C.

Furnace

Usually used in large-scale refineries. Offers a wide range of heating temperatures and requires no thermal oil consumption compared to hot oil boilers. Furnaces are typically 18-20 meters tall.

2. WHAT ARE THE CATEGORIES OF WASTE PRODUCED FROM WASTE OIL REFINERY?

Waste is generally in 4 categories: Gas, Oily Water, Oil Sludge, and Used Adsorbents.

Gas

Can be purified before emission or burned in a furnace.

Oil Sludge

Can be used for burning or as raw material for making bitumen.

Oily Water

Must be purified by specific facilities or handled by a professional recycler.

Used Adsorbent

Can be used for burning or handed to a professional recycler.

3. WHAT WILL BE THE YIELD OF BASE OIL AND BYPRODUCTS FROM FOSSIL WOOD WASTE OIL REFINERY?

The typical yield from a waste oil refinery will be:

4. WHAT IS THE QUALITY OF BASE OIL TO BE PRODUCED BY YOUR MACHINE?

The quality of base oil is able to meet API Group 1 and 1+ standards, which can be as good as virgin base oil after the Fossil Wood unique refining process. This base oil can be either sold directly or further blended with additives for making new engine oil.

Contact us for test reports of the base oil produced by our waste oil refineries.

Our Advantages

- Proven FW Series technology with global recognition

- Complete turnkey solutions from design to commissioning

- Comprehensive after-sales support and maintenance services

- Compliance with international environmental and quality standards

- Customized solutions tailored to specific requirements

- Expert technical support and operator training