Specialty Fluids & Additives Manufacturing

Comprehensive blending plants for brake fluids, coolants, transformer oils, additives, VI blending, AdBlue, and waste oil processing

Specialty Fluids & Additives

Discover our comprehensive range of plant & technology solutions, meticulously designed for diverse industrial needs. Our offerings encompass state-of-the-art facilities that optimize production processes, enhance product quality, and ensure environmental compliance.

Our comprehensive specialty fluids manufacturing encompasses brake fluids, engine coolants, antifreeze solutions, transformer oils, additive blending plants, VI blending, AdBlue production, and waste oil processing - each designed for specific applications with superior performance characteristics.

With our expertise and commitment to excellence, we empower industries to achieve operational efficiency, regulatory adherence, and sustainability goals seamlessly.

Specialty Fluids Plant Overview

Watch our comprehensive specialty fluids and additives manufacturing system in action, showcasing production of coolants, transformer oils, and advanced additive blending.

Blending Plants for Specialty Fluids and Additives

Discover our comprehensive range of plant & technology solutions, meticulously designed for diverse industrial needs. Our offerings encompass state-of-the-art facilities that optimize production processes, enhance product quality, and ensure environmental compliance.

Coolants & Antifreeze Making Plants

Innovative cooling and antifreeze solutions

Transformer Oil Plants

Advanced electrical insulation oil production

Additive Plants

Efficient additive manufacturing facilities

VI Blending Plants

Cutting-edge viscosity index blending

AdBlue Plants

Sustainable AdBlue production facilities

Waste & Used Oil Plants

Eco-friendly waste oil processing

Our Commitment to Excellence

With our expertise and commitment to excellence, we empower industries to achieve operational efficiency, regulatory adherence, and sustainability goals seamlessly. Explore our integrated solutions today and revolutionize your manufacturing operations for a brighter, greener future.

Specialty Fluids & Additives Technology

Our comprehensive specialty fluids manufacturing encompasses brake fluids, engine coolants, antifreeze solutions, transformer oils, additive blending plants, VI blending, AdBlue production, and waste oil processing - each designed for specific applications with superior performance characteristics.

Engine coolant and antifreeze protect engines from overheating or freezing, lubricate moving parts like the water pump, head gaskets, cylinder, and piston, and transfer heat to keep vehicles in optimal condition.

Transformer oils are vital in electrical systems, derived from virgin paraffinic and naphthenic crude oils, enhanced by high-pressure hydrogenation and hydro-treatment for superior electrical properties.

Additive blending plants manufacture complete additive packages for lubricants and greases, meeting API specifications and providing comprehensive solutions for various industrial applications.

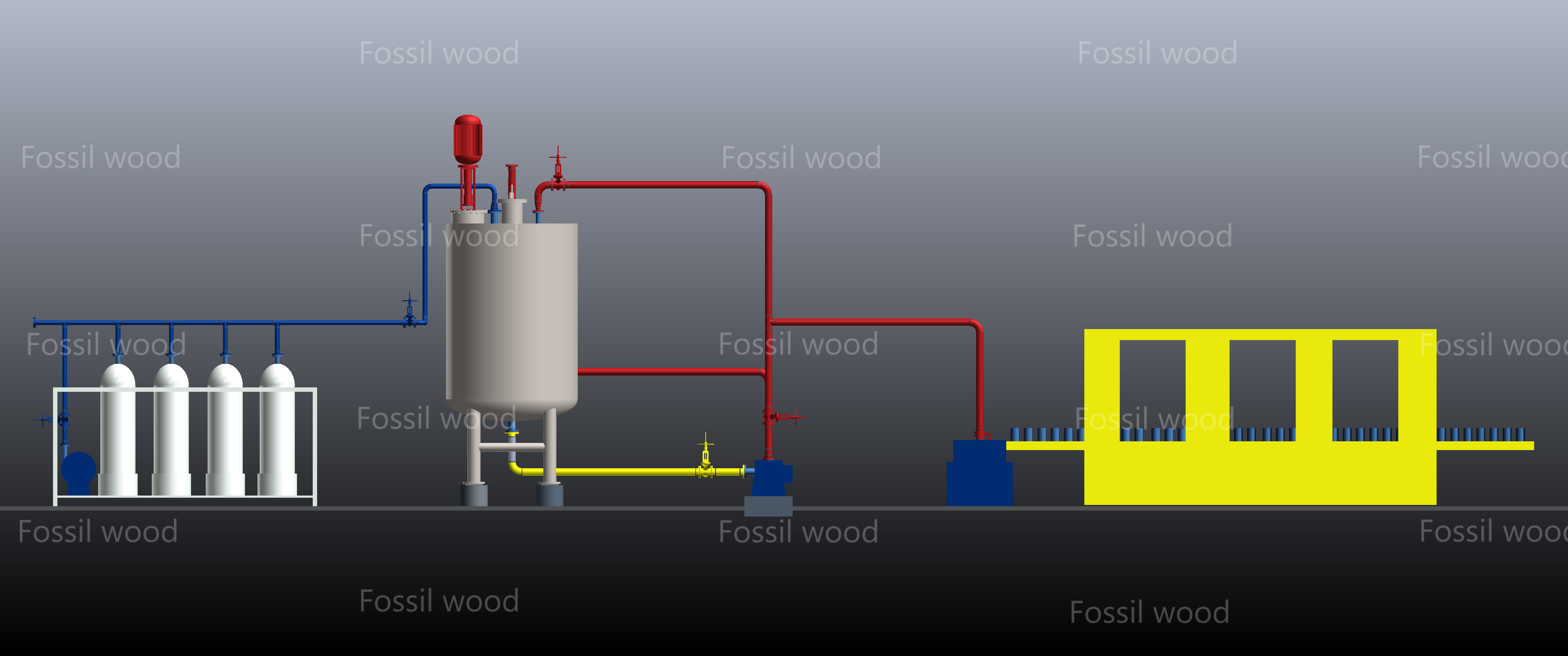

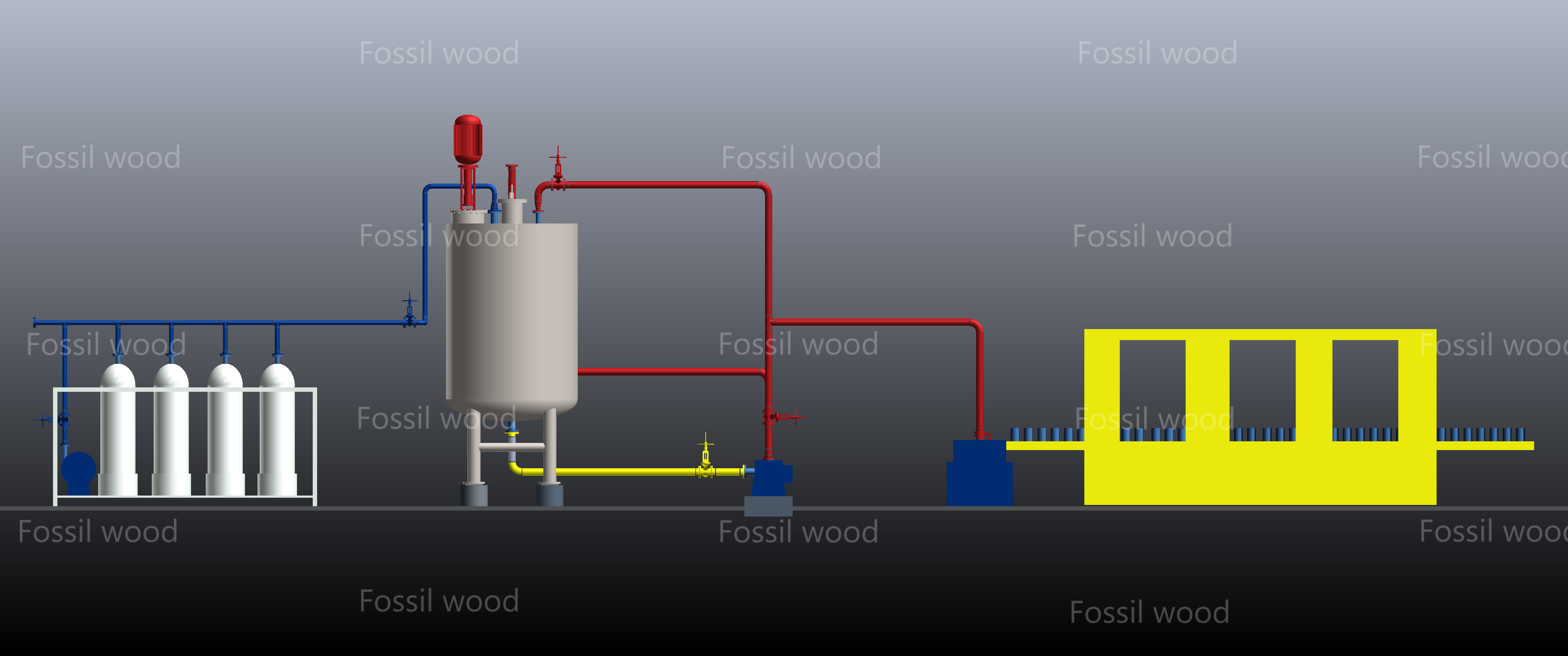

COOLANTS & ANTIFREEZE MAKING PLANTS

CAPACITY: 1,000 TO 10,000 LTRS/DAY

About Coolants and Antifreeze

Coolants and antifreeze protect engines from overheating or freezing and lubricate moving parts like the water pump, head gaskets, cylinder, and piston. They transfer heat and provide antifreeze protection to keep cars running optimally.

Engine coolant is used with liquid cooling systems, which consist of components like the water pump, radiator, fan, and thermostat. Coolant continuously cools the engine, preventing overheating or freezing.

It's primarily a mixture of ethylene glycol or propylene glycol mixed with water and additives. Coolants are also used in other heat transfer applications, such as HVAC chillers and solar water heaters.

Their purpose is to prevent physical stresses and catastrophic deformation of rigid enclosures at extreme temperatures. Compounds are added to reduce the freezing point and inhibit corrosion in cooling systems.

The term "engine coolant" is widely used in the automotive industry for its primary function of conductive heat transfer.

PROPERTIES OF A GOOD COOLANT

- •GOOD HEAT TRANSFER

- •PROTECTION AGAINST DEPOSITS

- •HIGH TEMPERATURE PROTECTION

- •SAFE TO USE WITH HARD WATER

- •SHOULD NOT DAMAGE INTERNAL COMPONENTS

- •REDUCED FOAMING TENDENCY

- •GOOD ANTICORROSION PROPERTIES

OUR SCOPE OF WORK

Each plant is supplied with complete equipment and systems for efficient coolant and antifreeze production:

- •Stainless steel mixers

- •Holding tanks

- •Transfer pumps

- •Pipelines

- •Valves

- •Instruments

- •Control panel with automation

- •Filling line

- •Complete set of required utilities

- •Lab testing equipments

Properties of a Good Coolant

Essential characteristics that ensure optimal performance and protection in cooling systems

Good Heat Transfer

Efficient thermal conductivity for optimal engine cooling.

Protection Against Deposits

Prevents scale and sludge formation in cooling systems.

High Temperature Protection

Maintains performance under extreme heat conditions.

Safe with Hard Water

Compatible with various water qualities and conditions.

Non-Damaging to Components

Protects internal engine components from corrosion.

Reduced Foaming

Minimizes air entrainment and foam formation.

Anti-Corrosion Properties

Advanced corrosion inhibitors for long-term protection.

Our Scope of Work

Each plant is supplied with complete equipment and systems for efficient coolant and antifreeze production

Stainless Steel Mixers

High-quality mixing equipment for precise formulations.

Holding Tanks

Storage vessels for raw materials and finished products.

Transfer Pumps

Efficient fluid transfer systems throughout the plant.

Pipelines & Valves

Complete piping network with automated control valves.

Instruments & Control Panel

Advanced automation and monitoring systems.

Filling Line

Automated packaging and filling operations.

Utilities

Complete set of required support systems.

Lab Testing Equipment

Quality control and testing instrumentation.

Transformer Oil Plants

Advanced manufacturing facilities for high-quality transformer oils with superior electrical properties

Transformer Oils Overview

Transformer oils are vital in electrical systems, derived from virgin paraffinic and naphthenic crude oils, enhanced by high-pressure hydrogenation and hydro-treatment. The process removes moisture and polar impurities, ensuring top-notch electrical properties.

These oils offer low pour points, outstanding oxidation stability, efficient cooling, and superior electrical attributes. Naphthenic mineral oil is a preferred choice for power transformer insulation due to its favorable characteristics, cost-effectiveness, and availability.

Transformer oil plays a crucial role in other electrical equipment like high-voltage switches and circuit breakers, stressing the importance of stability at high temperatures for uninterrupted operation.

Performance & Contamination

High viscosity supports electrical insulation, while low viscosity aids heat dissipation and fluid circulation. A significant concern is the susceptibility of transformer oils to contamination by water, dirt, and fibers, which can compromise electrical properties.

These contaminants can lead to arcing and dielectric breakdown. While these events don't immediately harm the machine, they significantly impact the oil, causing thermal breakdown. Low-temperature oxidation inhibitors and additives are used to mitigate degradation.

Transformer Oil Plant Equipment

Blending & Storage Tanks

Specialized tanks for transformer oil blending and storage.

Filtration & Vacuum Degasification

Advanced filtration and degasification units for purity.

Absorbent Columns

Columns for removing impurities and contaminants.

Homogenization Tank

Tanks for uniform mixing and consistency control.

Laboratory Instruments

Specialized testing equipment for electrical properties.

Standards & Specifications

Performance standards for transformer oils are established by renowned committees like IEC, CIGRE, and BIS, ensuring consistency and compatibility across diverse electrical systems.

Additive Blending Plants

Complete plant and technology for manufacturing additive packages used for lubricants and greases

Additive Package Manufacturing

Fossil Wood offers complete plant and technology for manufacturing additive packages used for manufacturing lubricants and greases. The packages are designed to meet API specifications such as SJ, SL, SM, and SN valid for passenger car motor oils and API grades of CH-4, CI-4, and CJ-4 valid for heavy duty diesel oils.

We provide comprehensive solutions including additives/components/packages (API, non-API, specialty), supply chain solutions, base oil sourcing, and inputs on setting up quality control lab, instrumentation, and testing capabilities.

Technical Expertise & Sourcing

Our technical expertise encompasses a wide range of additive categories and sourcing capabilities, ensuring we can meet the most demanding specifications and requirements for various lubricant applications.

From base oils (Group I through Group V) to finished lubricants, we provide end-to-end solutions that optimize machinery performance and longevity across diverse industrial applications.

Additive Categories & Technical Expertise

Antioxidants

Prevent oxidation and extend oil life

- •Aminic

- •Phenolic

- •PANA

Anti-Wear (AW) Agents

Protect metal surfaces from wear

- •Ashless AW

- •ZDDPS (Primary, Secondary, Mixed)

Corrosion Inhibitors

Prevent metal corrosion in lubricants

- •Alkyl Thiadiazoles

- •Fatty Acids/Amines/Half-Esters

Detergents

Keep engine parts clean

- •Low & High TBN Sulfonates

- •Phenates

- •Salicylates

Dispersants

Prevent sludge and deposit formation

- •PIBSI & Mannich Based

- •Functionalized with Boron & Phosphorus

- •Antioxidants

Extreme Pressure (EP)

Protect under extreme pressure conditions

- •Sulphur Based-SIB

- •Polysulfides

- •Sulfurized Olefins & Esters

Pour Point Depressants (PPDs)

Improve low-temperature flow properties

- •PMA

- •Styrene-Ester

- •Fumarate Based

Viscosity Index Improvers (VIIs)

Maintain viscosity across temperature ranges

- •Olefin-Copolymers (OCPs)

- •Star Polymers

- •Polymethacrylate (PMA) Based

API Specifications

Passenger Car Motor Oils

Heavy Duty Diesel Oils

Base Oils

Group I, Bright Stocks, Group II Re-refined, Group II, Group II+, Group III, Group IV (PAOs), and Group V (Esters)

Technical Expertise & Sourcing Capabilities

ANTIOXIDANTS

Aminic, Phenolic, & PANA

ANTI-WEAR (AW) AGENTS

Ashless AW & ZDDPS (Primary, Secondary, Mixed)

CORROSION INHIBITORS

Alkyl Thiadiazoles, Fatty Acids/Amines/Half-Esters

DETERGENTS

Low & High TBN Sulfonates, Phenates, & Salicylates

DISPERSANTS

PIBSI & Mannich Based; Functionalized with Boron & Phosphorus, & Antioxidants

EXTREME PRESSURE (EP)

Sulphur Based-SIB, Polysulfides, Sulfurized Olefins & Sulfurized Esters

PACKAGES

ATF, Engine Oil, Gear Oil, Hydraulic, Industrial, Grease, & Metalworking

POUR POINT DEPRESSANTS (PPDS)

PMA, Styrene-Ester, & Fumarate Based

VISCOSITY INDEX IMPROVERS (VIIs)

Olefin-Copolymers (OCPs), Star Polymers, & Polymethacrylate (PMA) Based

BASE OILS

Gr. I, Bright Stocks, Gr. II Re-refined, Gr. II, Gr. II+, Gr. III, Gr. IV (PAOs), and Gr. V (Esters)

FINISHED LUBES

Experience an extensive range of lubricants for various applications. Explore high-quality engine oils, gear oils, automatic transmission fluids (ATFs), hydraulic fluids, and industrial oils designed to optimize your machinery's performance and longevity. Our selection also includes compressor and refrigeration lubricants, jet turbine oils, cutting oils for precision machining, 2/4-stroke oils for engines, shock absorber fluids for smooth rides, way lubricants for heavy-duty equipment, chain lubricants for seamless operation, paper machine oils for reliable production, as well as specialized oils like aluminium roll oils, steel roll oils, and copper roll oils for specific industrial needs. Discover the right lubricant solutions tailored to your equipment's requirements and enhance its efficiency and durability.

Finished Lubricants

Experience an extensive range of lubricants for various applications. Explore high-quality engine oils, gear oils, automatic transmission fluids (ATFs), hydraulic fluids, and industrial oils designed to optimize your machinery's performance and longevity.

Engine Oils

High-quality engine oils for various applications

Gear Oils

Specialized gear lubrication solutions

Automatic Transmission Fluids (ATFs)

Advanced transmission fluid technology

Hydraulic Fluids

Industrial hydraulic system lubricants

Industrial Oils

Comprehensive industrial lubrication solutions

Compressor & Refrigeration

Specialized compressor and refrigeration oils

Jet Turbine Oils

Aviation-grade turbine lubrication

Cutting Oils

Precision machining cutting fluids

2/4-Stroke Oils

Two and four-stroke engine oils

Shock Absorber Fluids

Smooth ride suspension fluids

Way Lubricants

Heavy-duty equipment way lubrication

Chain Lubricants

Seamless chain operation lubricants

Paper Machine Oils

Reliable paper production lubrication

Roll Oils

Aluminium, Steel, and Copper roll oils

Coolant Composition & Applications

Purpose & Function

The purpose of coolant is to prevent physical stresses and catastrophic deformation at extreme temperatures. Compounds are added to reduce the freezing point and inhibit corrosion.

The term "engine coolant" is widely used in the automotive industry for its primary function of conductive heat transfer, ensuring optimal engine performance and longevity.

Applications & Benefits

Beyond automotive applications, coolants are used in HVAC chillers and solar water heaters, demonstrating their versatility in heat transfer systems.

The continuous cooling process maintains engine efficiency while preventing damage from thermal stress, making it essential for modern engine technology.

Manufacturing Capacity

Our plants are designed to meet diverse production requirements with flexible capacity options